Tiny Holes, Big Impact

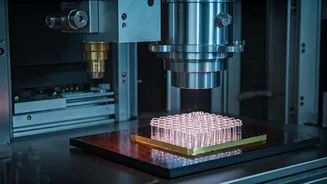

The research team at IMEC has demonstrated the successful production of nanopores using ASML's EUV machines. These nanopores are incredibly small, each

a few nanometers wide. To put this in perspective, their diameter is approximately 10,000 times finer than a human hair. Their minute size is central to their functionality in biomedical applications. These microscopic perforations are poised to play a key role in molecular sensing, offering the potential to revolutionize how we identify and analyze individual molecules within biological samples. The ability to precisely manufacture these tiny structures at scale represents a major advance, opening new avenues for medical breakthroughs.

How Nanopores Work

Nanopores function by interacting with molecules in a unique way. Biomedical sensors leverage this interaction to identify and analyze various molecules. When an ionic current passes through a nanopore, scientists measure it. As molecules traverse through, they modulate the current, providing information about their size, structure, charge, and interactions. Distinct electrical signatures help differentiate between molecules, resulting in high sensitivity. This process enables precise detection of diverse molecules, including viruses, proteins, and DNA. Adjusting nanopore size also enables filtration and molecular data storage. The electrical signatures allow for the identification of different molecules. This creates possibilities for accurate molecule identification and analysis.

EUV’s Production Advantages

Existing methods for producing nanopores have been described as slow, expensive, and limited to lab settings. However, IMEC’s innovative method using EUV machinery marks a significant shift. The team successfully fabricated nanopores with diameters as small as ~10nm across the entire wafer. This breakthrough is particularly exciting because it encompasses mass production, precision, and reproducibility. These advancements address the bottlenecks in the adoption of nanopore-based sensors. This new method overcomes the limitations of previous methods to make them more accessible for medical equipment manufacturers. The innovation in precision is vital for creating high-quality, uniform nanopores at a scale that was previously unattainable.

Mass Production Benefits

The research highlights a step towards cost-effective mass production. The ability to create these nanopores on a large scale has promising implications for the advancement of medical technology. While acknowledging the high cost and demand for ASML EUV equipment, the researchers are optimistic. This method will likely make nanopore-based sensors more affordable, accelerating their integration into medical devices and diagnostics. This advancement will ensure accessibility to the equipment needed for mass production. It is a necessary advancement as it should lower the financial burden placed on medical equipment manufacturers.