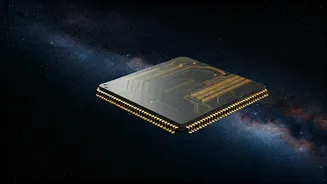

Chipmaking in Space

The space environment presents significant challenges for electronics, particularly radiation exposure. Traditional chips are vulnerable to this radiation,

which can lead to malfunctions or complete failure. To mitigate these issues, the development and use of radiation-hardened chips have become increasingly vital. These specialized chips are designed to withstand the harsh conditions of space, ensuring the reliable operation of satellites, spacecraft, and other space-based technologies. Several companies are joining forces to modernize chipmaking for space. The goal is to provide the required equipment to withstand radiation exposure and ensure their operational lifespan. Recent announcements highlight the importance of secure and reliable technology for space exploration.

Partnerships Emerge

Collaboration is key in the advancement of space technology. Several strategic partnerships have been formed to push the envelope of chip manufacturing for space applications. These alliances typically involve collaborations between established aerospace companies and semiconductor manufacturers. For example, BAE Systems and GlobalFoundries have joined forces to improve chipmaking. These collaborations leverage the expertise and resources of all partners involved to develop advanced radiation-hardened chips. By combining their knowledge, companies can create cutting-edge technology that meets the stringent demands of space missions. Strategic partnerships help to accelerate the pace of innovation and increase the reliability of space-based systems.

Meeting Space Requirements

The design and manufacturing of chips for space differ greatly from those for terrestrial applications. The chips must undergo rigorous testing to ensure they can function correctly in extreme environments, including temperature fluctuations, vacuum conditions, and high levels of radiation. These specialized chips must be designed to withstand ionizing radiation, which can cause single-event upsets (SEUs) and other problems. These radiation-hardened chips employ different design techniques and materials to mitigate radiation effects. The goal is to build chips that are far more resistant to damage. This can be achieved through changes in design, material selection, and manufacturing. These techniques play a vital role in ensuring that all space missions succeed, protecting critical components from radiation.

Future Advancements

The future of space exploration is heavily dependent on continued innovation in chip technology. Ongoing research is centered on further reducing the size and power consumption of radiation-hardened chips. New manufacturing techniques, such as FinFET technology, are being adapted for space applications. The use of more advanced materials with enhanced radiation resistance is also underway. These advancements aim to improve the performance, reliability, and longevity of space-based systems. These developments will facilitate more ambitious and complex space missions. They ensure that space exploration can proceed efficiently and safely in the face of harsh environmental conditions.