Printing a Revolution

The Massachusetts Institute of Technology (MIT) research team achieved a significant breakthrough by developing a novel 3D-printed aluminum alloy. This

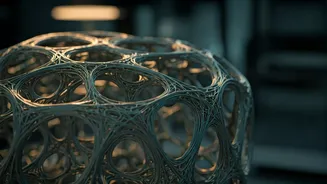

alloy boasts impressive strength, being five times more robust than traditional cast aluminum. Mohadeseh Taheri-Mousavi, the project lead, envisions a future where this material is used in airplane engine fan blades, enhancing their performance. This discovery highlights the remarkable capabilities of 3D printing in creating new and improved versions of metals. This method allows metals to cool and solidify quickly, preserving their structure. The rapid freezing of the alloy is achieved after it is melted by the laser, which creates its unique properties. This is a game-changer for several industries.

Strength and Sustainability

This new 3D-printed aluminum alloy offers several advantages over conventional aluminum. It is not only significantly stronger but also lighter and more heat-resistant. These properties make it an ideal choice for applications that demand high performance under extreme conditions, such as airplane engine fan blades. The use of lighter yet stronger metals can lead to a reduction in energy consumption across various industries. This, in turn, can transform energy-intensive sectors like transportation. The result of this is that engineers can reduce energy waste and lead to greater conservation of natural resources. This also makes a more sustainable planet with lower pollution a realistic target for the future.

Applications Abound

The applications of this innovative alloy extend far beyond aerospace. Researchers have identified promising uses in various fields, including vacuum pumps, data center cooling devices, and high-end automobiles. The development also emphasizes the potential of 3D printing for sustainable manufacturing. This innovation paves the way for the creation of new materials with significant advantages over traditional metals. This could drive advancements in green technology. It also allows changes in our approach to construction with eco-friendly building materials. This discovery opens doors for anyone wanting to design 3D-printed alloys. The unique characteristics of the 3D printing process, particularly the fast cooling rate, are key to achieving these remarkable material properties.

Future Directions

Looking ahead, the MIT researchers plan to refine the 3D printing techniques further. They aim to enhance additional alloy properties to move towards practical applications. This ongoing research is expected to unlock even greater potential. The team is dedicated to exploring how this technology can address specific challenges. Furthermore, they plan to expand the functionality of 3D-printed alloys. They aim at providing new solutions for several industries. With the advancements in sustainable manufacturing, there is hope for a brighter future. By adopting these new technologies, the focus is on a reduction in energy consumption and a significant shift towards green technology.