Fueling Test Hiccups

NASA recently conducted a critical wet dress rehearsal (WDR) for the Artemis 2 mission, aiming to practice fueling the Space Launch System (SLS) rocket.

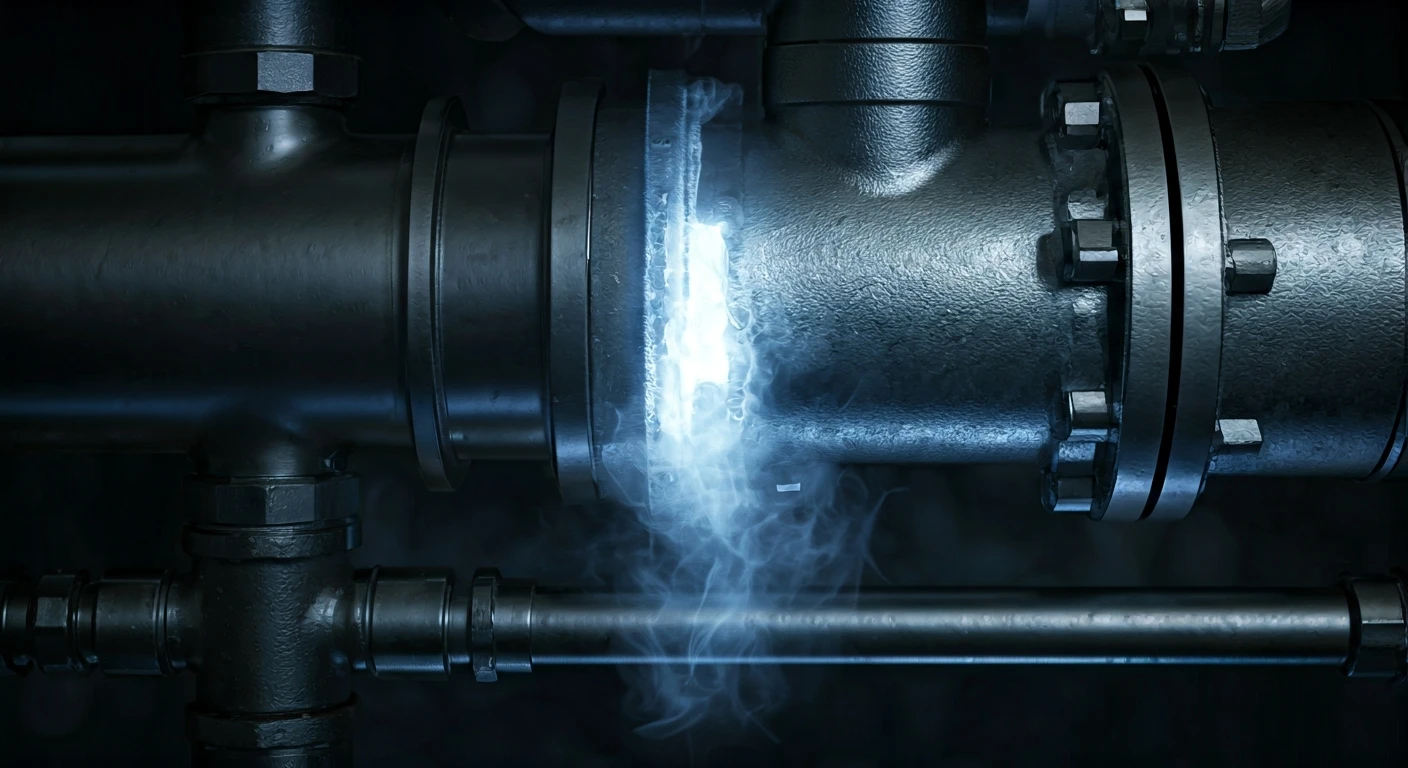

The test, however, was interrupted by a hydrogen leak detected during the final countdown stages. This incident led to the postponement of the mission's launch during the current window, which closes on February 11th. It's important to note that this wasn't the only leak encountered; an earlier one occurred during the rapid filling of the liquid hydrogen tank. Engineers managed to resolve this first leak by employing a technique refined during the Artemis 1 campaign: warming up seals in a quick-disconnect fitting. This method, after a couple of tries, proved effective. The second leak, however, presented a more immediate concern as it rapidly intensified during tank pressurization, indicating an issue that required further investigation on the ground.

Echoes of Artemis 1

The reappearance of hydrogen leaks during the Artemis 2 WDR brought back memories of the challenges faced during the Artemis 1 mission, which experienced multiple leaks during its practice runs and two scrubbed launch attempts in 2022. NASA officials had previously stated that significant changes to both hardware and operational procedures were implemented following the Artemis 1 campaign, based on the valuable lessons learned from that test flight. Charlie Blackwell-Thompson, the Artemis launch director, emphasized that Artemis 1 served as a crucial learning experience. Despite these assurances, the recurring nature of the leaks during the Artemis 2 test raised questions about the thoroughness of the post-Artemis 1 evaluations. John Honeycutt, chair of the Artemis 2 Mission Management Team, defended the agency's efforts, highlighting extensive component-level testing of systems like the liquid hydrogen interfaces. He acknowledged, however, that there are inherent limitations to component-level testing compared to evaluating the fully integrated vehicle and ground systems, admitting that these latest leaks were unexpected.

Investigating the Causes

Several factors are being considered as potential contributors to the persistent hydrogen leaks. One significant aspect is the complex environmental stress and strain the vehicle endures during its rollout from the Vehicle Assembly Building to Launch Complex 39B. This journey, according to NASA Associate Administrator Amit Kshatriya, is intricate and can impact the vehicle's structural integrity. Another point of discussion is the remarkably low flight rate of the SLS. Artemis 2 marks only the second launch of this massive rocket, with the previous one occurring in November 2022. NASA Administrator Jared Isaacman noted that while the SLS is the fastest route to returning humans to the moon, it is not the most economical or sustainable long-term solution. The bespoke nature of SLS hardware, often crafted by specialized artisans, means each component can have unique characteristics, potentially influencing how it behaves under operational conditions. Engineers are meticulously examining the integrated vehicle and ground systems to pinpoint the exact cause of the leaks, whether it's a misalignment, deformation, or debris affecting the seals.

Progress and Future Plans

Despite the hydrogen leak challenges, the recent wet dress rehearsal provided valuable data and operational experience for other critical systems. This included the inaugural use of a new, larger liquid hydrogen storage tank at the launch pad, as well as crucial tests for closing the Orion spacecraft's hatches. Blackwell-Thompson pointed out the limited opportunities to perform such integrated vehicle checks, particularly when the rocket is loaded with cryogenic propellants, emphasizing the tight timeline and sequential nature of these operations. To address the hydrogen leak issues and complete the countdown phases missed in the first test, NASA plans to conduct a second wet dress rehearsal. A date for this follow-up test has not yet been set. Importantly, officials have indicated that the rocket will likely remain at Launch Complex 39B, as the necessary repairs can be performed on-site, avoiding a costly and time-consuming rollback to the Vehicle Assembly Building. This allows NASA to target the next launch opportunity, running from March 6th to March 11th. Should they miss this window, a rollback might become necessary to service components like batteries in the SLS upper stage that cannot be addressed at the pad.