Additive Manufacturing on Deck

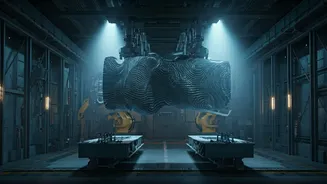

The advent of 3D printing, also known as additive manufacturing, is ushering in a new era of efficiency and innovation for the U.S. Navy, particularly

aboard its formidable aircraft carriers. This advanced technology allows for the rapid and cost-effective production of essential components directly in the field, mirroring its success in environments like the International Space Station. By enabling the creation of mission-critical parts on-demand, the Navy is seeing substantial improvements in operational readiness and a marked decrease in logistical challenges. This paradigm shift is moving 3D printing from a nascent experimental phase to an integral part of maintenance, repair, and sustainment strategies, fundamentally altering how warships are kept combat-ready and efficient in their operations.

Slashing Lead Times Dramatically

The implementation of 3D-printed components on U.S. aircraft carriers has yielded astonishing results, most notably a reduction in lead times exceeding 70%. This dramatic improvement is particularly impactful when it comes to complex metal parts, which traditionally require extensive manufacturing processes and long waiting periods. For instance, the Navy successfully printed a metal valve manifold assembly for the pump room of the Gerald R. Ford-class aircraft carrier Enterprise (CVN 80). This achievement bypasses the lengthy and often costly methods of conventional metal casting, especially for bespoke or low-volume parts. The precision additive manufacturing process, conducted without the need for molds, allows for the swift creation of intricate designs, enabling faster outfitting and repair, even during critical operational windows. This capability is a testament to the Navy's strategic partnerships and its successful integration of this technology.

Innovative Materials and Partnerships

The versatility of 3D printing extends to a wide array of materials, including plastics, metals, and resins, allowing the Navy to tailor solutions to specific needs. In a notable collaboration with Marotta Controls, a chilled water valve was manufactured using laser powder bed fusion, a technique that fuses powdered material layer by layer. The chosen material, Inconel 625, a nickel superalloy known for its exceptional corrosion resistance, ensures durability and longevity in harsh maritime environments. This successful installation on a U.S. Navy ship underscores the reliability and growing acceptance of 3D-printed parts. Further demonstrations of this technology's prowess include a partnership with the U.S. Coast Guard to print critical equipment for a submarine using a polymer 3D printer, and a trilateral effort involving the U.S., Australia, and the U.K. to install 3D-printed parts on the fast-attack submarine USS Vermont, proving the widespread benefits and adaptability of additive manufacturing across naval branches and international collaborations.