The Hygroscopic Nature of Fibers

Tea towels, commonly crafted from cotton or linen, owe their water-absorbing capabilities to their inherent hygroscopic nature. These natural cellulose

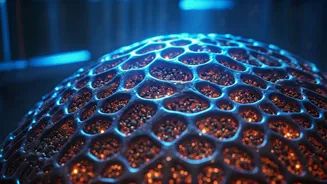

fibers are designed to attract and hold water molecules. However, the effectiveness of a textile extends beyond just the fiber type; it's a nuanced interplay of fiber, yarn construction, fabric weave, and any treatments applied during the manufacturing process. Water retention occurs both within the fibers themselves and in the interstitial spaces between them. This is why the very structure of the fabric plays a crucial role in its absorbency. Consider bath towels, which typically feature a thick terry pile construction. This design significantly amplifies the surface area, facilitating rapid water wicking into the fabric. In contrast, tea towels can feature various weaves like plain, twill, or waffle cloth. Plain weaves, often used for visually appealing printed designs, demand a smooth surface for clean printing. Waffle weaves, characterized by their distinct three-dimensional texture, are exceptionally adept at absorbing moisture due to their increased surface area, much like their terry cloth counterparts.

Unveiling the Age Advantage

The superior drying performance of an older, worn tea towel over a brand-new one can be attributed to three primary factors. Firstly, many new textiles are treated with silicone-based softeners to enhance their feel and wrinkle resistance, making them more attractive in retail settings. Ironically, these finishes are often water-repellent, creating a barrier that hinders absorption. A simple solution is to wash new tea towels in hot water before their first use to eliminate this coating. Secondly, textiles undergo significant transformations during their initial washing cycles, typically up to six. Manufacturing processes often involve stretching yarns, and washing allows these yarns to relax into a more natural, tension-free state, a phenomenon known as 'relaxation shrinkage.' While this might slightly reduce the towel's dimensions, its mass remains constant, leading to a denser, thicker fabric. In waffle weave towels, this shrinkage can accentuate the 3D texture, further boosting absorbency by increasing the fabric's surface geometry. This effect has also been observed in terry bath towels. Thirdly, the natural aging process of fabric through repeated washing and drying leads to minor surface wear. This wear causes small fibers to gently lift from the fabric surface, creating a fluffier, more 'hairy' texture. Initially, very smooth tea towels exhibit poor absorbency because water struggles to wet the surface, often beading up due to a high contact angle. As washing introduces more surface texture and raises fibers, the contact angle decreases, making the fabric more receptive to wetting. Waffle fabrics, with their inherently irregular surfaces, already benefit from favorable contact angles, enhancing their absorbency from the outset. Ultimately, washing cultivates increased surface texture, leading to superior absorption.

Beyond Tea Towels: A Textile Revelation

The insights gained from understanding tea towel performance extend to a broader appreciation of all household textiles. The comforting 'worn-in' sensation associated with beloved bath towels, kitchen cloths, and even bed linens is not merely sentimental; it reflects genuine improvements in performance. After repeated laundering, these textiles shed their initial factory finishes and settle into their true structural potential. This means that before considering replacing your old tea towels with new ones, recognize that their frayed edges and faded patterns are indicators of their maturation and optimization. When acquiring new home textiles, it is highly recommended to wash them at least once prior to use. This preliminary wash effectively removes any residual manufacturing finishes, such as sizing agents or softeners, allowing the fibers to begin their natural process of relaxation and enhancing their inherent absorbency and performance right from the start. This practice ensures that your new textiles can begin their journey towards becoming the reliable, high-performing items you expect.