By Rajesh Kumar Singh

CHICAGO, Jan 22 (Reuters) - GE Aerospace CEO Larry Culp on Wednesday defended the jet-engine industry's pricing practices against airline industry complaints that soaring maintenance costs and engine shortages are straining their businesses. Airlines say supply-chain snags, long waits for shop visits and limited spare engine availability have given manufacturers more power to raise prices.

That is a point International Air Transport Association (IATA) Director General Willie Walsh

has highlighted as the industry struggles with grounded aircraft and repair backlogs.

Culp, in an interview with Reuters, said the engine maker's pricing reflects the scale of investment required to develop and support complex propulsion systems, and the value engine makers provide over decades-long service lives.

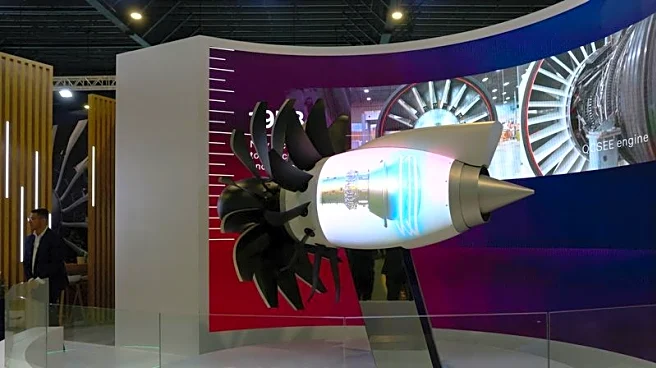

"We invest heavily in technology," Culp said, pointing to its roughly $3 billion in annual research and development spending. He said GE has tried to be clear with customers about "our place in the value chain: the investments we make, the risks we take on, and the value that we create."

The dispute comes at a moment of unusual strain for the aerospace supply chain.

Turnaround times at engine repair shops for newer-generation engines are about 150% higher than pre-pandemic benchmarks, according to Bain & Company, as airlines keep older aircraft flying longer while waiting for delayed new deliveries.

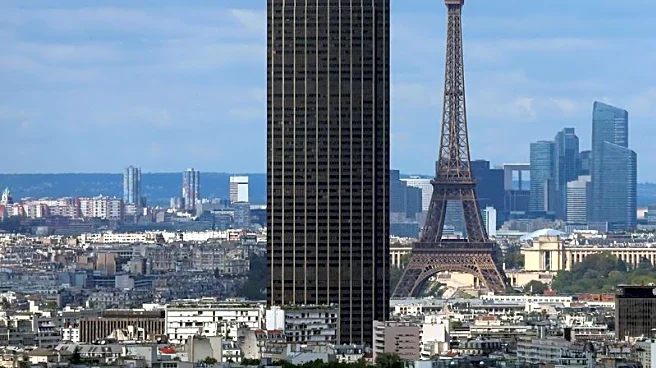

Culp said GE Aerospace is trying to ease airline frustration by accelerating durability improvements to the LEAP engine family, built through CFM International, GE's joint venture with France's Safran and the sole engine supplier for Boeing's 737 MAX.

(Reporting by Rajesh Kumar Singh; Editing by Mark Potter and Jan Harvey)