What's Happening?

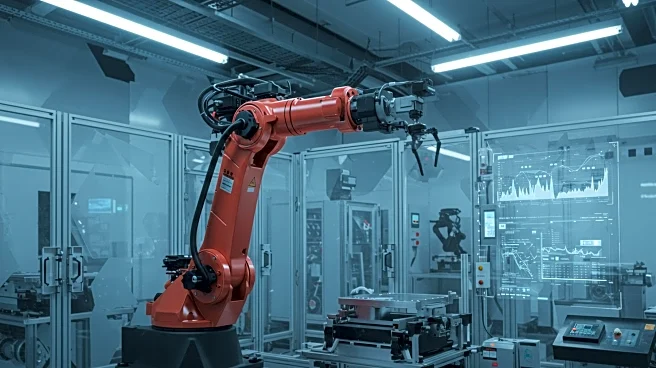

GE Appliances (GEA) is advancing its manufacturing processes by adopting a lean technology strategy aimed at increasing efficiency and product quality across its plants. The company is leveraging learnings from its Roper plant, which has benefited from technology implementations at GEA's laundry and dishwasher machine plants. This strategy involves the use of Automated Mobile Robots (AMRs) and Automated Guided Vehicles (AGVs), which are being considered for deployment based on the specific needs of each plant. As GEA's portfolio of proven technologies expands, the company is planning for increased capital expenditures (CapEx) to accommodate the integration of these solutions. The strategic outlook for each plant includes a detailed plan for the next five years, focusing on robotics and digitization integration to enhance operational efficiency.

Why It's Important?

The implementation of a lean technology strategy by GE Appliances is significant as it reflects a broader trend in the manufacturing industry towards automation and digital integration. By increasing CapEx to support these technologies, GEA aims to improve product quality and operational efficiency, which can lead to cost savings and competitive advantages in the market. This move is likely to influence other manufacturers to adopt similar strategies, potentially leading to a shift in industry standards. The focus on data-driven decision-making ensures that technology deployments are tailored to the specific needs of each plant, optimizing resource allocation and minimizing waste.

What's Next?

GE Appliances plans to continue its strategic technology integration over the next five years, with a focus on enhancing plant efficiency and product quality. The company will likely monitor the performance of AMRs and AGVs at the Roper plant and other facilities to determine the best practices for future deployments. As the manufacturing landscape evolves, GEA may explore additional technologies to further automate and digitize its operations, potentially setting new benchmarks for efficiency and innovation in the industry.