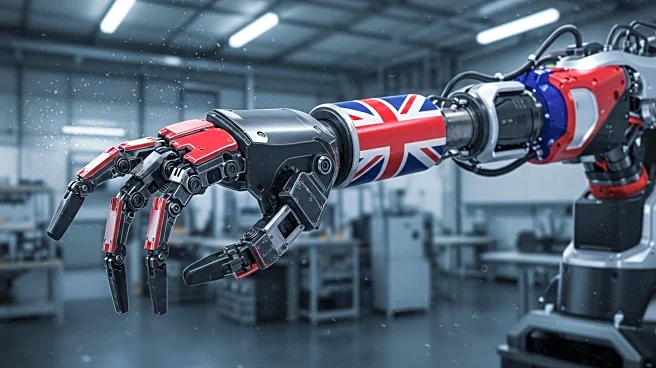

What's Happening?

British manufacturing companies have been struggling to keep pace with international competitors in the adoption of robotics and AI technologies. Over the past two decades, these companies have fallen significantly in global automation rankings. The lack of adequate training in digital skills necessary to leverage innovative technologies is a major factor contributing to this lag. Efforts are being made to address these challenges, including initiatives like Made Smarter, which supports digital transformation among manufacturers. Additionally, new facilities such as the Warwick Agri-Tech pilot are being established to drive agricultural innovation using advanced robotics.

Why It's Important?

The slow adoption of robotics and AI in British manufacturing has significant implications for the country's economic growth and global competitiveness. Closing the gap in automation could potentially add £150 billion to the UK GDP by 2035. This highlights the importance of investing in digital skills and technology to enhance productivity and innovation. The manufacturing sector is crucial for the UK's export economy, and improving its technological capabilities could strengthen its position as a leading export engine. The initiatives underway aim to modernize the industry, boost productivity, and ensure sustainable growth.

What's Next?

Efforts to modernize British manufacturing are expected to continue, with increased focus on digital transformation and skills training. The Made Smarter initiative and similar programs will likely expand to support more manufacturers in adopting advanced technologies. The success of pilot facilities like Warwick Agri-Tech could lead to further investments in agricultural innovation, enhancing food resilience and sustainability. As the industry evolves, stakeholders will need to address challenges related to infrastructure, training, and investment to fully realize the potential benefits of automation.

Beyond the Headlines

The push for automation in British manufacturing also raises ethical and cultural considerations, such as the impact on employment and the need for reskilling workers. As technology advances, there will be discussions around balancing innovation with job preservation and ensuring equitable access to digital skills training. Long-term shifts in the industry could redefine traditional manufacturing roles and require new approaches to workforce development.