What's Happening?

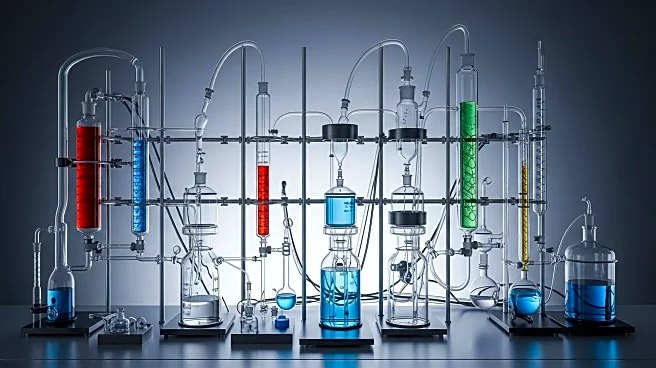

Apeloa Pharmaceutical, a leading contract development and manufacturing organization (CDMO) in China, is advancing its commitment to sustainability by adopting flow chemistry in its manufacturing processes. Flow chemistry, which involves running chemical reactions as a continuous stream rather than in discrete batches, offers significant advantages in terms of safety and environmental impact. Apeloa has invested over USD 20 million in this technology over the past decade, aiming to reduce energy consumption, emissions, and resource use. The company’s flow chemistry platform supports the entire drug development lifecycle, from early-stage research to commercial production, and is managed by a team of over 50 scientists and engineers. This approach allows Apeloa to handle high-risk reactions safely and efficiently, improving yields and reducing waste.

Why It's Important?

The adoption of flow chemistry by Apeloa Pharmaceutical represents a significant shift towards more sustainable practices in the pharmaceutical industry. By reducing the environmental footprint of drug manufacturing, Apeloa is addressing growing concerns about the industry's impact on the planet. This move is likely to influence other pharmaceutical companies to consider similar technologies, potentially leading to widespread improvements in process safety and sustainability. The flow chemistry market is expected to grow significantly, driven by regulatory support and scientific advancements, which could further enhance the industry's ability to produce innovative drugs efficiently and responsibly.

What's Next?

Apeloa Pharmaceutical plans to continue refining its flow chemistry platform, expanding its capabilities and expertise across its global sites. The company has published a white paper detailing its achievements and future goals, which may serve as a blueprint for other organizations looking to adopt similar practices. As the flow chemistry market grows, Apeloa is positioned to lead in the development of safer and more sustainable pharmaceutical manufacturing processes. The company’s ongoing investment in this technology suggests a commitment to long-term environmental responsibility and innovation.

Beyond the Headlines

The shift to flow chemistry not only impacts environmental sustainability but also enhances the safety of chemical processes. By minimizing the risks associated with explosive or hazardous reactions, Apeloa is setting a new standard for safety in pharmaceutical manufacturing. This approach could lead to broader regulatory changes, encouraging more companies to adopt safer and more efficient methods. Additionally, the integration of AI and automation in flow chemistry processes may further optimize production, reducing costs and increasing accessibility to high-quality pharmaceuticals.