What's Happening?

A recent survey conducted by the Reshoring Initiative and Regions Recruiting has revealed that a stronger skilled workforce in the U.S. could significantly enhance reshoring efforts among manufacturers. The 2025 USA Reshoring Survey, which included 500 U.S. manufacturers, identified the availability of skilled labor as the primary driver for reshoring decisions. Original Equipment Manufacturers (OEMs) indicated that with a sufficient workforce, they would reshore 30% of their products currently offshored. Other factors such as tariffs, currency value changes, tax cuts, and regulatory adjustments also influence reshoring decisions, albeit to a lesser extent. The survey highlighted the importance of shifting OEMs to a Total Cost of Ownership (TCO) model, which could reshore $200 billion of manufacturing without government intervention. Manufacturers are also reevaluating sourcing strategies to mitigate supply chain risks and are considering the benefits of proximity to engineering and faster delivery times.

Why It's Important?

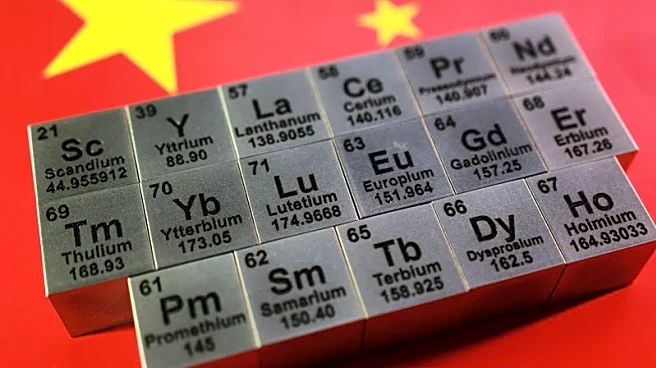

The findings underscore the critical role of workforce development in the U.S. manufacturing sector's ability to compete globally. A robust skilled workforce could prevent the forecasted shortfall of 2.1 million manufacturing jobs by 2030, which could result in a $1 trillion loss to GDP. Reshoring not only reduces geopolitical risks but also strengthens supply chain resilience and sustainability. It encourages investment in infrastructure and workforce development, which in turn bolsters the U.S. economy and creates well-paying jobs. The survey also highlights the potential risks associated with continued reliance on manufacturing in China, including geopolitical tensions related to Taiwan. By reshoring, manufacturers can mitigate these risks and enhance their market share through improved customer satisfaction and faster delivery times.

What's Next?

Manufacturers are expected to continue evaluating their sourcing strategies, with a focus on reshoring and nearshoring to reduce geopolitical risks and improve supply chain resilience. The survey suggests that implementing a national industrial policy could further accelerate reshoring efforts by leveling the cost playing field and providing the necessary workforce. OEMs are likely to explore partnerships with contract manufacturers to leverage technical solutions and reduce lead times. As geopolitical tensions persist, particularly concerning China and Taiwan, manufacturers may increasingly prioritize reshoring as a strategic move to safeguard their operations.

Beyond the Headlines

The reshoring trend reflects broader shifts in global manufacturing dynamics, where geopolitical considerations are increasingly influencing business decisions. The emphasis on workforce development highlights the need for educational and training programs to equip workers with the skills required for modern manufacturing roles. Additionally, the focus on TCO models suggests a growing awareness among manufacturers of the hidden costs associated with offshoring, prompting a reevaluation of long-term business strategies. These developments could lead to a more sustainable and resilient manufacturing sector in the U.S., with implications for economic policy and international trade relations.