What is the story about?

What's Happening?

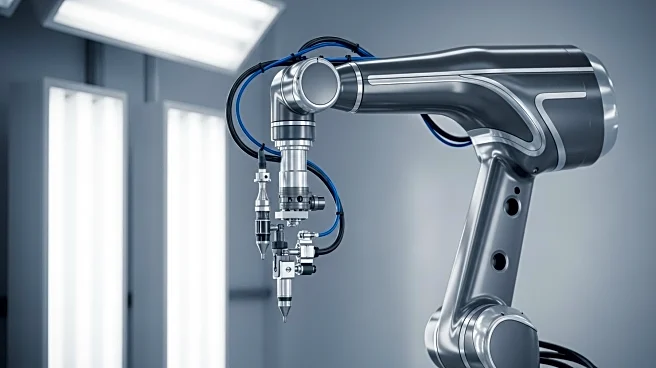

FANUC, a leading robotics company headquartered in Japan, has secured a significant order to supply a state-of-the-art paint system to a European luxury carmaker. The order includes nearly 50 robots designed to paint car bodies and plastic add-on parts such as bumpers. The project, managed entirely by FANUC, features an innovative cabin painting concept that reduces the number of cabins and robots required. This approach, along with FANUC's advanced application technology, ensures fast changeover times and minimal paint loss. The company's paint lab near Stuttgart, Germany, was instrumental in securing the order, showcasing FANUC's capability to deliver high-quality, efficient painting solutions.

Why It's Important?

This development underscores the growing reliance on robotics in the automotive industry, particularly in luxury car manufacturing, where precision and quality are paramount. FANUC's ability to provide durable and sustainable robotic solutions positions it as a key player in the industry, potentially influencing other manufacturers to adopt similar technologies. The use of robots not only enhances production efficiency but also improves workplace safety by minimizing human exposure to hazardous materials. This order could lead to further advancements in robotic applications across various sectors, promoting innovation and sustainability.

What's Next?

As FANUC implements this project, the company may see increased interest from other automotive manufacturers seeking to enhance their production capabilities. The successful deployment of these robots could lead to further orders and collaborations, expanding FANUC's influence in the global market. Additionally, the automotive industry may witness a shift towards more automated processes, driven by the need for efficiency and quality. Stakeholders, including car manufacturers and technology providers, will likely monitor the project's progress to assess its impact on production standards and operational sustainability.

Beyond the Headlines

The integration of advanced robotics in manufacturing raises questions about the future of labor in the industry. While robots improve efficiency and safety, they also challenge traditional employment models, potentially leading to workforce displacement. Companies may need to invest in retraining programs to equip workers with skills relevant to automated environments. Furthermore, the emphasis on sustainable operations aligns with global efforts to reduce environmental impact, highlighting the role of technology in achieving these goals.