What's Happening?

CNH Industrial has completed a significant digital transformation project at its Zedelgem plant in Belgium, known as the 'Accelerator Project.' This €150 million initiative, in collaboration with Flanders Make and other partners, aims to enhance digital manufacturing

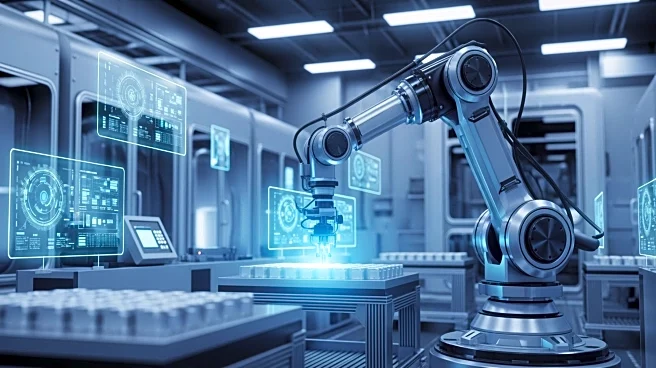

capabilities. The project has introduced advanced production technologies, including automation and AI-supported quality control, to improve production efficiency and flexibility. The Zedelgem facility now features a new flexible assembly line and advanced planning systems, which have increased the plant's ability to manage a 30% rise in active parts. This transformation supports the production of the New Holland CR11 combine harvester, a next-generation flagship product.

Why It's Important?

The completion of the Accelerator Project positions CNH Industrial and the Flanders region as leaders in digital and sustainable manufacturing. By integrating cutting-edge technologies, CNH enhances its global competitiveness and operational agility. The project also exemplifies successful public-private cooperation, with financial support from the Flemish government aiding in modernizing operations and securing high-tech employment. This initiative not only strengthens CNH's manufacturing capabilities but also contributes to the industrial renaissance of Flanders, setting new standards for global competitiveness in the manufacturing sector.

What's Next?

The successful implementation of the Accelerator Project at Zedelgem may serve as a model for similar digital transformation initiatives in other CNH facilities worldwide. The project's scalability and potential for international expansion could further enhance CNH's global manufacturing footprint. Additionally, the collaboration with Flanders Make and other partners may lead to future innovations and advancements in digital manufacturing, reinforcing Flanders' position in the global manufacturing chain.