What's Happening?

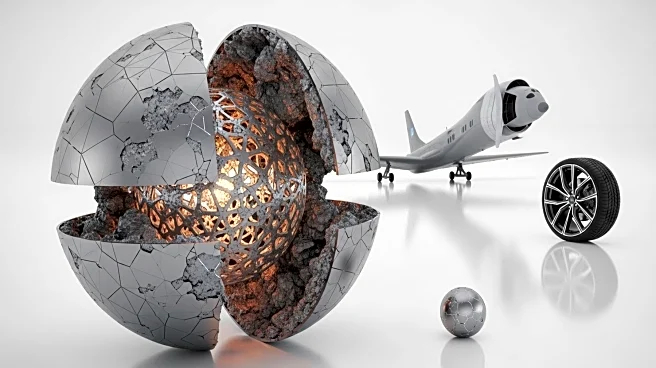

The global powder metallurgy market is anticipated to grow significantly, reaching a valuation of $10.2 billion by 2033, according to recent projections. This growth is driven by a compound annual growth rate (CAGR) of 14.9% from 2025 to 2033. The market's expansion is largely attributed to the increasing demand for lightweight and high-performance components in the aerospace and automotive sectors. Powder metallurgy offers near-net-shape capabilities, resulting in low scrap rates and material savings. The technology is particularly beneficial in the aerospace industry, where reducing aircraft weight can lead to substantial fuel savings. Additionally, the automotive industry's shift towards electrification is fueling demand for powder metallurgy components, with companies like GKN Powder Metallurgy securing large contracts for electric vehicle parts.

Why It's Important?

The projected growth of the powder metallurgy market is significant for several industries, particularly aerospace and automotive, which are major drivers of demand. The aerospace sector benefits from the lightweighting capabilities of powder metallurgy, which can lead to considerable fuel efficiency improvements. In the automotive industry, the transition to electric vehicles is creating a robust market for high-performance components made through powder metallurgy. This growth indicates a shift towards more sustainable and efficient manufacturing processes, with potential cost savings and environmental benefits. Companies involved in powder metallurgy are likely to see increased opportunities for innovation and expansion, impacting their competitive positioning and market share.

What's Next?

As the powder metallurgy market continues to expand, companies are expected to invest in new technologies and facilities to meet rising demand. Strategic investments and facility expansions are underway, with firms like Ampal Inc. and Neo investing in new production lines and manufacturing facilities. The focus on sustainability is also driving companies to reduce their carbon footprint, with ambitious targets set for emission reductions. The evolving labor market will require advanced skill development to support the technological sophistication of the powder metallurgy sector. Educational initiatives, such as the METAL program, are being launched to cultivate the next generation of experts in this field.

Beyond the Headlines

The growth of the powder metallurgy market is not only a reflection of technological advancements but also of broader trends towards sustainability and efficiency in manufacturing. The process's ability to minimize waste and energy usage aligns with global efforts to reduce environmental impact. Additionally, the integration of Industry 4.0 technologies for process control and quality assurance is enhancing the capabilities of powder metallurgy, making it a key player in the future of manufacturing. As industries continue to prioritize lightweight and high-performance materials, powder metallurgy is poised to play a crucial role in shaping the future of mobility and aerospace design.