What's Happening?

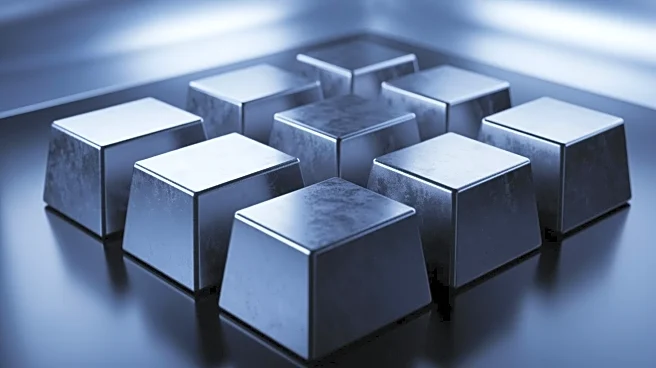

China's Jiangxi Province has announced a reallocation of its rare earth oxide processing capacity, shifting the global supply landscape. This strategic move involves redistributing existing capacity among

local entities without increasing total production. The reallocation aims to enhance operational efficiency and environmental compliance while maintaining China's control over the rare earth market. The changes reflect China's broader strategy of industrial consolidation, focusing on optimizing infrastructure performance rather than expanding production volumes.

Why It's Important?

The reallocation of rare earth processing capacity in Jiangxi is significant as it underscores China's continued dominance in the global rare earth market. By consolidating operations, China can maintain tight control over supply chains, impacting international stakeholders who rely on these critical materials for technology and manufacturing. The move highlights the strategic importance of rare earths in global supply chains and the need for countries to diversify their sources to mitigate risks associated with supply concentration.

What's Next?

The capacity reallocation in Jiangxi may prompt other Chinese provinces to adopt similar strategies, further centralizing control over rare earth processing. International buyers may need to explore alternative sources and develop long-term supply agreements to ensure access to these critical materials. The consolidation trend could also lead to increased investment in rare earth processing capabilities outside China, as countries seek to reduce their dependence on Chinese supply chains.

Beyond the Headlines

The focus on operational efficiency and environmental compliance in Jiangxi's capacity reallocation reflects a broader trend towards sustainable industrial practices. By modernizing facilities and integrating circular economy principles, China aims to improve resource recovery rates and reduce environmental impact. This approach aligns with global efforts to enhance supply chain resilience and sustainability, highlighting the need for international cooperation in developing sustainable solutions for critical minerals processing.