What is the story about?

What's Happening?

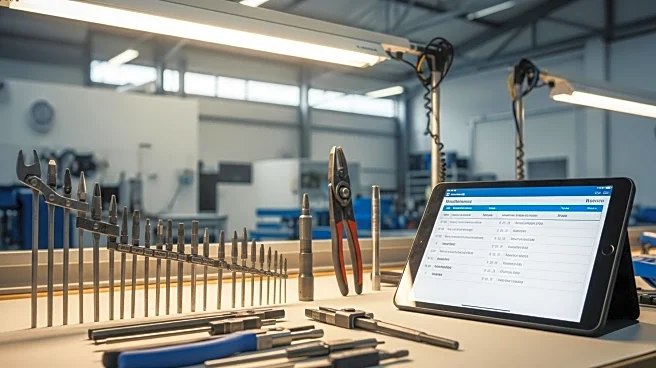

Manufacturers are increasingly focusing on maintenance, repair, and overhaul (MRO) as a strategic approach to enhance cost efficiency and sustainability. Traditionally viewed as a back-office function, MRO is now recognized as crucial for minimizing downtime, controlling costs, and extending the lifespan of critical assets. The global MRO market is projected to grow significantly, driven by automation and predictive maintenance technologies. This shift is motivated by the need to refurbish and repair components rather than replace them, offering faster and cheaper solutions. For example, refurbishing a pump shaft can cost significantly less and take less time compared to purchasing a new one. This approach not only saves money but also supports environmental objectives by reducing waste and demand for raw materials.

Why It's Important?

The adoption of MRO practices is vital for manufacturers facing challenges related to cost and sustainability. By choosing refurbishment over replacement, manufacturers can achieve 'as new' performance at a fraction of the cost and time, thereby enhancing resilience and credibility. This approach aligns with the growing demand for sustainable practices, as it reduces waste and supports the circular economy. Additionally, MRO helps manufacturers comply with regulations and meet customer expectations for responsible operations. The strategic use of MRO can transform it from a cost-saving measure to a value-creating process, improving component performance and extending operational life.

What's Next?

Manufacturers are expected to increasingly integrate predictive maintenance technologies, such as IoT sensors and data analytics, to anticipate failures and make refurbishment a proactive process. This shift will further enhance the strategic advantage of MRO, reducing downtime and waste while providing greater control over operations. As industries systematically adopt refurbishment, significant savings in costs, carbon emissions, and downtime are anticipated. The continued authorization of processes like Chrome 6 under strict compliance demonstrates the potential for MRO to contribute to innovative and sustainable manufacturing models.

Beyond the Headlines

The broader implications of embracing MRO include strengthening supply chains and enhancing resilience against geopolitical shocks and raw material shortages. By prioritizing repair and reuse, manufacturers can maintain production schedules and customer supply even in challenging circumstances. The rise of predictive tools further supports this transition, enabling manufacturers to transform MRO into a strategic advantage. This approach not only addresses immediate operational needs but also positions manufacturers to meet long-term sustainability goals.