What's Happening?

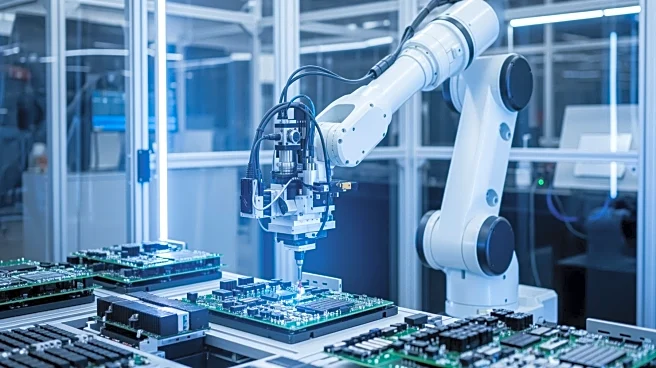

Robotics is transforming the landscape of electronics manufacturing, driving a new era of precision and scalability across global factories. As electronic devices become smaller and production cycles accelerate,

automated systems are increasingly taking over tasks that were previously challenging for human workers. This shift is evident in the integration of robotics into production lines, which enhances efficiency by reducing errors and increasing throughput. Companies worldwide are adopting robotics to future-proof operations, signaling the rise of a global robotic manufacturing ecosystem. The integration of robotics in electronics manufacturing has evolved from being a novelty to a necessity, with foundational automation systems connecting robots, conveyors, and inspection machines in high-volume electronics lines. This transformation is crucial for manufacturers facing tighter margins, smaller components, and shorter product life cycles, as robotics provide speed, precision, and minimal waste.

Why It's Important?

The integration of robotics into electronics manufacturing is significant for several reasons. It allows manufacturers to maintain competitiveness in a market characterized by rapid technological advancements and consumer demand for smaller, more efficient devices. By automating processes, companies can reduce labor risks, improve yields, and adapt quickly to product variants and changeovers. This shift not only enhances operational efficiency but also supports the industry's ability to meet the growing demand for electronic products. Robotics in manufacturing also contributes to the development of smart factories, where modularity, flexible cells, and advanced software play a central role. As companies like ABB Robotics and NEXTY Electronics lead the way in integrating robotics into manufacturing processes, the industry is poised for further innovation and growth.

What's Next?

The future of electronics manufacturing will likely see further advancements in robotics technology, with companies continuing to invest in automation to enhance production capabilities. ABB Robotics plans to spin off its robotics business as a separate entity by Q2 2026, highlighting the strategic importance of robotics in manufacturing. This move could lead to increased focus and investment in developing more sophisticated robotic solutions tailored to the needs of electronics manufacturers. Additionally, companies like NEXTY Electronics are demonstrating the potential of smart factories, where robotics integration, logistics automation, and real-time monitoring are key components. As the industry evolves, manufacturers will need to continue adapting to new technologies and processes to remain competitive in the global market.

Beyond the Headlines

The integration of robotics into electronics manufacturing raises several ethical and cultural considerations. As automation becomes more prevalent, there may be concerns about job displacement and the need for workforce retraining. Companies will need to address these challenges by investing in education and training programs to equip workers with the skills needed to operate and maintain advanced robotic systems. Additionally, the shift towards automation may lead to changes in workplace culture, with an increased emphasis on collaboration between humans and machines. As robotics technology continues to advance, manufacturers will need to navigate these complexities to ensure a smooth transition to automated production processes.