What's Happening?

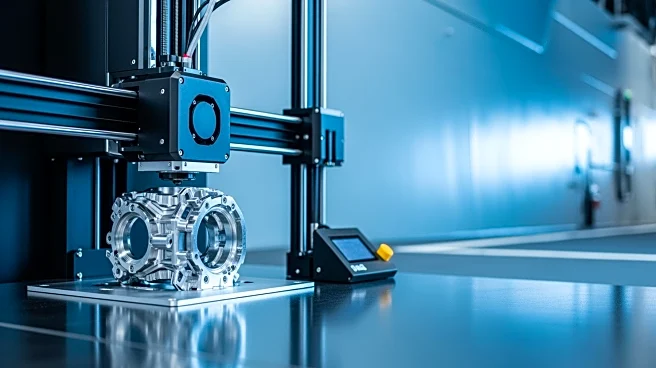

The U.S. Navy has expanded its use of 3D printing, or additive manufacturing (AM), to enhance fleet operations, marking a significant shift from experimental use to a fully integrated capability. In 2025, the Navy achieved a 70% reduction in lead times

for parts production, integrating AM components into complex platforms like aircraft carriers and submarines. This initiative is part of a broader strategy to modernize the maritime industrial base, improve logistics resilience, and strengthen alliances through the AUKUS partnership with the UK and Australia. The Navy's efforts have resulted in significant cost savings and increased operational readiness.

Why It's Important?

The integration of 3D printing into Navy operations represents a transformative approach to military logistics and maintenance. By reducing production times and costs, the Navy can maintain a more agile and responsive fleet, crucial for national security and defense readiness. This technological advancement also enhances the Navy's ability to collaborate with international allies, promoting interoperability and shared capabilities. The successful implementation of AM could serve as a model for other branches of the military and industries, highlighting the potential of 3D printing to revolutionize manufacturing and supply chain processes.