What's Happening?

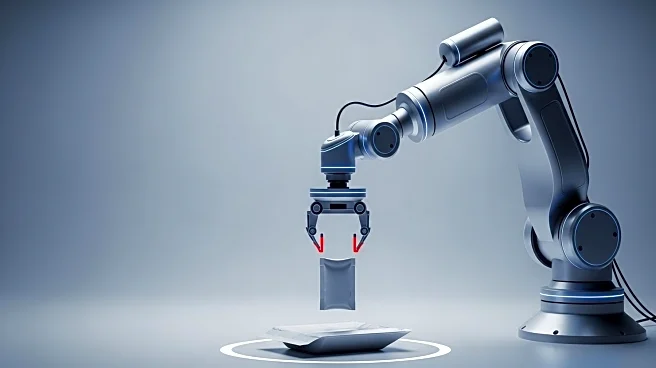

Fanuc America has developed an innovative 'vanishing tray' system to address space constraints in manufacturing facilities. This system utilizes pneumatic cylinders to drop empty trays through gravity

feed to a lower conveyor, effectively eliminating the need for additional floor space to return trays. The inverted robot configuration allows for more efficient use of space, providing easy access for operators during maintenance and product changeovers. South Coast Robotics, a Fanuc authorized system integrator, implemented this system for a home-care products manufacturer, automating the packaging line operations. The system is designed to handle up to 30 different stock keeping units (SKUs), accommodating rapid changeovers and improving throughput rates from 30 to 36 bottles per minute.

Why It's Important?

The introduction of the vanishing tray system by Fanuc America represents a significant advancement in manufacturing efficiency, particularly for facilities with limited space. By optimizing the use of floor space and enhancing automation capabilities, manufacturers can increase productivity and reduce operational costs. This system is particularly beneficial for industries with diverse product lines requiring frequent changeovers, such as home-care products. The ability to handle multiple SKUs efficiently can lead to increased competitiveness and market responsiveness. Additionally, the reduction in manual labor and improved throughput rates can contribute to higher profitability and sustainability in manufacturing operations.

What's Next?

As manufacturers continue to seek solutions for space constraints and efficiency improvements, the adoption of systems like Fanuc America's vanishing tray system is likely to increase. Companies may explore further automation and integration of advanced technologies to streamline operations and enhance productivity. Stakeholders in the manufacturing sector, including system integrators and technology providers, may collaborate to develop customized solutions for specific industry needs. The success of this system could prompt other manufacturers to consider similar innovations, potentially leading to widespread changes in packaging and production processes.

Beyond the Headlines

The implementation of advanced automation systems like the vanishing tray system raises important considerations regarding workforce dynamics and skill requirements. As manual operations are replaced by automated systems, there may be a shift in the types of skills needed in manufacturing roles, emphasizing technical expertise and system management. Additionally, the environmental impact of increased automation, such as energy consumption and waste management, may become a focal point for manufacturers aiming to balance efficiency with sustainability.