What's Happening?

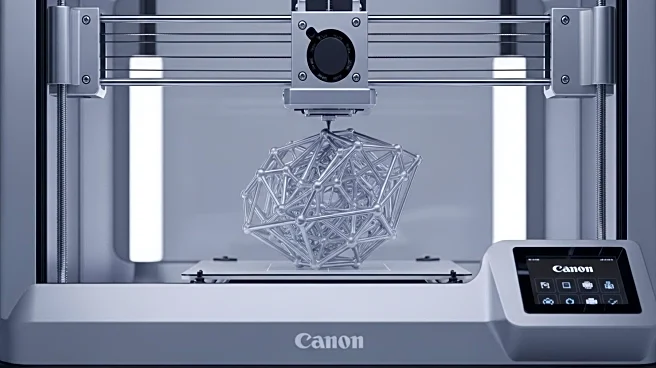

The World Platinum Council (WPIC) has emphasized the evolving role of platinum group metals (PGMs) in 3D printing technology. Over a decade ago, Japan's Tanaka Precious Metals developed the first platinum-based powder for 3D printers, enabling the creation of complex shapes with platinum's corrosion resistance and strength at high temperatures. This advancement has sparked interest in the aerospace industry, where PGMs are used in manufacturing satellite thrusters with longer lifetimes and reduced metal content. The WPIC notes that additive manufacturing with PGM powders is also beneficial for industries requiring high-temperature, corrosion-resistant parts, such as glass fiber manufacturing. Additionally, 3D printing reduces inventory needs by allowing on-demand production of items from stored powders.

Why It's Important?

The integration of PGMs in 3D printing represents a significant technological advancement, offering new possibilities for industries like aerospace and manufacturing. By enabling the production of complex, high-performance components, PGMs can enhance product durability and efficiency, potentially reducing costs and material waste. This development is crucial for industries seeking to innovate and improve sustainability. Furthermore, the ability to produce items on demand through 3D printing can streamline supply chains, reduce storage costs, and increase flexibility in manufacturing processes. The WPIC's focus on PGMs highlights their potential to drive advancements in additive manufacturing and expand its applications.

Beyond the Headlines

The use of PGMs in 3D printing also has implications for the jewelry industry, as demonstrated by the commercial launch of platinum-based jewelry collections. This application showcases the potential for 3D printing to revolutionize jewelry design and fabrication, offering novel designs and experiences. The technology's ability to create intricate and customizable pieces could lead to new trends in jewelry, appealing to consumers seeking unique and personalized products. Additionally, the adoption of 3D printing in jewelry could reduce production costs and environmental impact, aligning with broader sustainability goals.