What is the story about?

What's Happening?

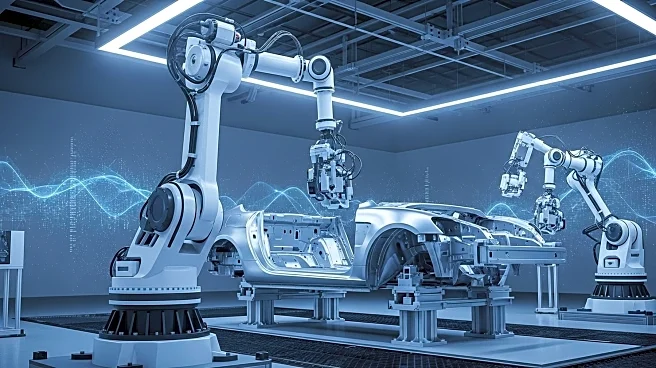

BMW has inaugurated a new AI car factory in Debrecen, Hungary, marking it as the company's most innovative production site globally. This facility is the first in BMW's network to operate entirely without fossil fuels and integrates advanced AI technologies for quality control and logistics. The factory will begin production of the all-electric BMW iX3, part of BMW's Neue Klasse series, which is expected to influence the brand's future model lineup. The site is equipped with autonomous transport systems and real-time data analytics, aiming to enhance production efficiency and sustainability.

Why It's Important?

The opening of BMW's AI-driven factory in Hungary represents a significant shift towards sustainable and technologically advanced automotive manufacturing. By utilizing AI for quality checks and logistics, BMW aims to reduce production costs and improve efficiency, potentially setting a new industry standard. This development is crucial for the automotive sector as it navigates the transition to electric vehicles and seeks to minimize environmental impact. The factory's focus on renewable energy and digital connectivity could influence other manufacturers to adopt similar practices, promoting a greener and more efficient industry.

What's Next?

BMW plans to implement the AI technologies used in the Debrecen factory across its global production network, starting with its Munich plant. The company aims to integrate these technologies into 40 new models by 2027, potentially transforming its manufacturing processes. The success of this factory could lead to further investments in AI and renewable energy within the automotive industry, encouraging other manufacturers to follow suit. Additionally, the factory's production of the BMW iX3 will contribute to the growing market for electric vehicles, supporting BMW's strategic goals in the EV sector.

Beyond the Headlines

The Debrecen factory's emphasis on AI and sustainability highlights broader trends in the automotive industry, including the push for digitalization and environmental responsibility. The use of AI for real-time quality control and logistics optimization could lead to significant advancements in manufacturing efficiency and product quality. Furthermore, the factory's reliance on renewable energy sources underscores the industry's commitment to reducing carbon emissions and promoting sustainable practices. These developments may influence regulatory policies and consumer expectations, driving further innovation and investment in green technologies.