What's Happening?

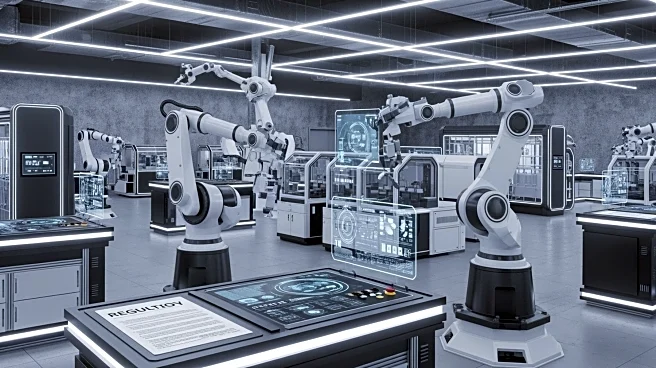

Sage, a partner at the upcoming Manufacturing Leaders’ Summit, is focusing on key topics such as regulation, compliance, supply chain management, and digitalization in the manufacturing sector. Andy Reid,

head of Sage’s ERP Product Marketing, highlights the importance of understanding material source production processes and the role of regulations in ensuring consumer transparency. He emphasizes the need for manufacturers to adopt digital tools for traceability and sustainability, particularly in energy usage during production. Reid also discusses the impact of geopolitical and economic disruptions on manufacturing locations, noting a trend towards reshoring in the UK and Europe. Sage's ERP systems are positioned as crucial for managing production processes and supply chain disruptions.

Why It's Important?

The insights shared by Sage underscore the critical role of digital transformation in enhancing manufacturing efficiency and compliance. As regulations evolve, manufacturers must adapt to ensure transparency and traceability, which are increasingly demanded by consumers. The reshoring trend in manufacturing could lead to more localized production, potentially reducing dependency on global supply chains. Sage's emphasis on digital tools highlights the importance of technology in mitigating production risks and improving sustainability. This shift could benefit manufacturers by reducing costs and enhancing product quality, while also addressing broader economic pressures such as inflation and rising trade costs.

What's Next?

Manufacturers are expected to continue integrating digital tools to enhance traceability and compliance. The adoption of ERP systems and automation will likely increase, helping manufacturers manage supply chain disruptions and improve production efficiency. As geopolitical and economic challenges persist, reshoring may become more prevalent, leading to changes in global manufacturing dynamics. Sage's focus on digital transformation suggests that manufacturers will need to balance automation with human involvement, ensuring that technology complements rather than replaces the workforce.

Beyond the Headlines

The push for digital transformation in manufacturing raises ethical considerations regarding workforce displacement and the need for skill development. As automation becomes more integrated, manufacturers must address potential job losses and invest in training programs to equip workers with new skills. The emphasis on sustainability and energy efficiency also highlights the environmental impact of manufacturing processes, prompting companies to consider greener practices. These developments could lead to long-term shifts in manufacturing strategies, prioritizing ethical and sustainable production.