What's Happening?

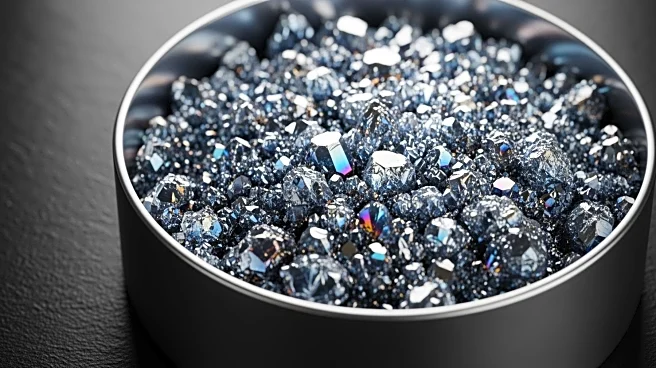

Mkango Resources has inaugurated a rare earth magnet production facility at Tyseley Energy Park in Birmingham, UK. This marks the first commercial rare earth magnet production in the UK in 25 years. The facility utilizes the patented hydrogen processing

of magnet scrap (HPMS) technology, capable of recovering over 400kg of rare earth alloy per batch. It can produce new sintered magnets from recycled rare earth alloy at a capacity of 100 tonnes per year on a single shift, with potential to increase to over 300 tonnes annually on multiple shifts. This development is part of the UK Government's 2025 Critical Minerals Strategy, aiming to meet 10% of annual critical mineral demand domestically and 20% through recycling by 2035.

Why It's Important?

The launch of this facility is significant for the UK's rare earth supply chain, reducing reliance on imports and enhancing domestic production capabilities. It supports the UK's strategy to secure critical minerals, essential for various industries including technology and defense. The facility's use of HPMS technology not only offers a cost advantage but also minimizes carbon footprint, aligning with environmental goals. This move could position the UK as a leader in sustainable rare earth production, potentially influencing global supply chains and reducing dependency on dominant producers like China.

What's Next?

The facility is expected to scale up operations in the UK and expand internationally, with plans underway in Germany and the US. This expansion could further strengthen the UK's position in the global rare earth market. The success of this facility may encourage further investments in similar technologies and facilities, contributing to a more resilient and sustainable supply chain for critical minerals.