What's Happening?

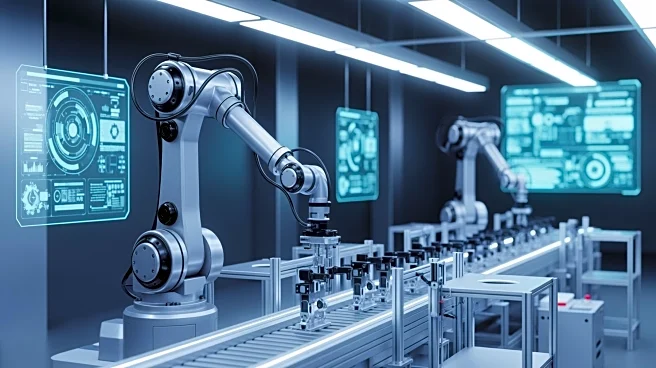

CNH Industrial has completed a €150 million digital upgrade at its Zedelgem plant in Belgium, in collaboration with Flanders Make and other partners. The project, known as the 'Accelerator Project,' aims

to enhance digital manufacturing capabilities and position Flanders as a leader in sustainable manufacturing. The investment has led to the development of a flexible assembly line and advanced planning systems, improving production efficiency and material flow. The project also supports the production of the New Holland CR11 combine harvester, which has increased production complexity by 30%.

Why It's Important?

This digital transformation is significant for CNH Industrial as it enhances the company's manufacturing capabilities and competitiveness in the global market. By integrating advanced digital technologies, CNH is setting a benchmark for sustainable and efficient manufacturing practices. The project also highlights the importance of public-private partnerships in driving innovation and economic growth in the manufacturing sector. The successful implementation of these technologies could serve as a model for other industries looking to modernize and improve sustainability.

What's Next?

As CNH Industrial continues to implement its digital strategies, the focus will be on maintaining production efficiency and quality while managing increased complexity. The company may explore further collaborations to expand its digital capabilities and enhance its competitive edge. Stakeholders will be monitoring the impact of these innovations on job creation and economic development in the region.