What's Happening?

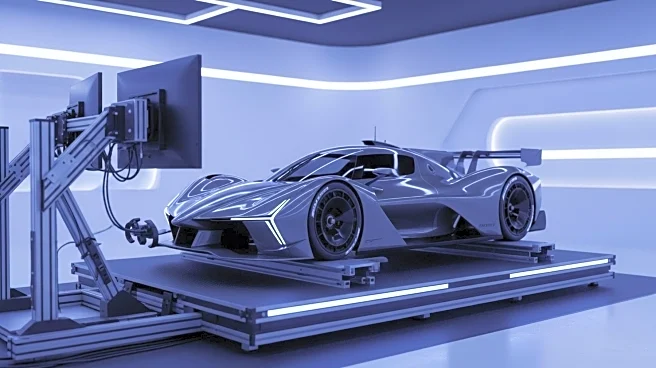

McLaren Automotive has installed a state-of-the-art Dynisma Motion Generator (DMG) simulator at its Technology Centre, significantly enhancing its virtual development capabilities. This advanced simulator provides realistic feedback and accurate correlation to real vehicle performance, allowing engineers and test drivers to explore vehicle characteristics and develop engineering solutions in a powerful virtual environment. The DMG simulator enables a Formula 1-level of motion simulation, offering insights into vehicle dynamics and performance. The first car to benefit from this technology is the McLaren W1, which has undergone a combined simulator validation and aerodynamic development program.

Why It's Important?

The installation of the DMG simulator marks a significant advancement in automotive development, allowing McLaren to streamline its engineering processes and improve vehicle performance. By integrating virtual development with real-world testing, McLaren can achieve greater efficiency and accuracy in its design and testing phases. This technology provides a competitive edge in the automotive industry, potentially leading to faster innovation cycles and improved vehicle designs. The ability to simulate and analyze vehicle dynamics in a virtual environment can reduce development costs and time, benefiting both the company and consumers.

What's Next?

The deployment of DMG technology in the development of the McLaren W1 serves as a proof of concept, paving the way for deeper integration of virtual development into future vehicle programs. McLaren is likely to continue leveraging this technology to enhance its vehicle lineup, potentially expanding its use to other models. The success of the DMG simulator may encourage other automotive manufacturers to adopt similar technologies, leading to broader industry changes in vehicle development processes.

Beyond the Headlines

The use of advanced simulation technology raises questions about the future of automotive testing and development. As virtual environments become more sophisticated, the reliance on physical testing may decrease, altering traditional engineering practices. This shift could impact employment in the sector, as skills related to virtual simulation become more valuable. Additionally, the environmental benefits of reduced physical testing could contribute to sustainability efforts within the industry.