What's Happening?

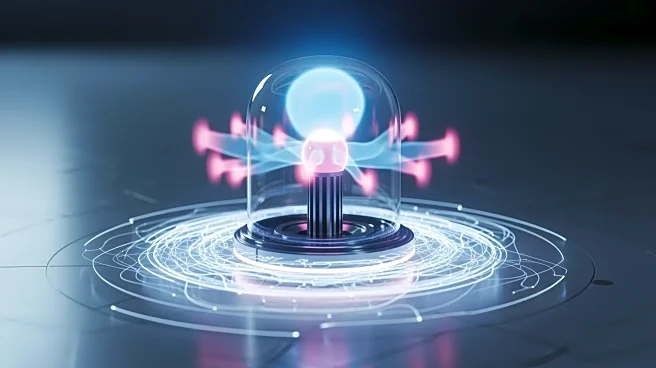

A new method for producing urea using plasma technology has been developed, offering a potentially more sustainable alternative to traditional processes. The technique involves a pulsed high-voltage plasma discharge

to activate air, generating NOx, which is then used in an electrocatalytic reduction step with CO2. The process achieves a high yield of urea with significant Faradaic efficiency. While the energy consumption is higher than conventional methods, the approach is less energy-intensive than other electrocatalytic routes, and could become economically viable with low electricity prices.

Why It's Important?

This development represents a significant step towards more sustainable chemical manufacturing processes. By utilizing plasma technology and renewable energy, the method addresses environmental concerns associated with traditional urea production, which is energy-intensive and relies on fossil fuels. The potential for economic viability with low electricity costs could make this approach attractive for large-scale adoption, contributing to the reduction of greenhouse gas emissions and supporting the transition to a more sustainable chemical industry.

What's Next?

Further research and development are needed to optimize the process and reduce energy consumption. The scalability of the technology and its integration into existing industrial systems will be key factors in its adoption. As renewable energy sources become more accessible, the economic feasibility of this method may improve, encouraging wider implementation. The success of this approach could inspire similar innovations in other areas of chemical manufacturing, promoting sustainability across the industry.