What's Happening?

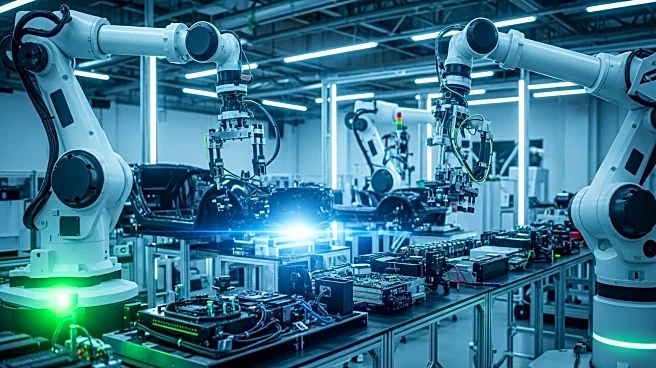

Henkel has completed a significant expansion of its manufacturing facility in Brandon, South Dakota, with an investment of approximately $30 million. This expansion has doubled the facility's size from 35,000 to 70,000 square feet, enhancing its capacity to produce high-performance materials for the electric vehicle (EV) and electronics industries. The facility, which is Henkel's North American flagship for thermal management and adhesives solutions, now includes additional mixers for high-volume production. The expansion is part of Henkel's strategy to support the long-term growth of these markets with sustainable solutions. The Brandon facility is also the first in Henkel's North American Adhesive Technologies business to achieve LEED certification, aiming for LEED Silver status.

Why It's Important?

The expansion of Henkel's facility is a strategic move to meet the growing demand for advanced materials in the EV and electronics sectors. By increasing production capacity, Henkel is positioning itself to play a crucial role in the supply chain for these rapidly evolving industries. The investment underscores Henkel's commitment to sustainability and innovation, aligning with broader industry trends towards greener and more efficient technologies. This development is likely to benefit the local economy in South Dakota through job creation and increased industrial activity, while also strengthening Henkel's market position in North America.

What's Next?

Henkel plans to continue its focus on innovation and sustainability, with the expanded facility supporting the production of materials essential for the performance and safety of automotive batteries and electronic components. The company is also enhancing its collaboration with customers through its new North America Battery Application Center in Michigan. As the EV and electronics markets grow, Henkel's expanded capabilities will be critical in meeting future demands. The company's ongoing digitization efforts at the Brandon facility, including paperless workflows and automated controls, are expected to further improve operational efficiency and sustainability.

Beyond the Headlines

Henkel's expansion reflects a broader industry shift towards sustainable manufacturing practices. Achieving LEED certification highlights the company's dedication to environmental responsibility, which could set a precedent for other manufacturers. The collaboration between industry, government, and community in this project exemplifies a successful model for economic development and innovation. As the EV market continues to expand, Henkel's role in providing essential materials could influence industry standards and drive further advancements in sustainable technology.