What's Happening?

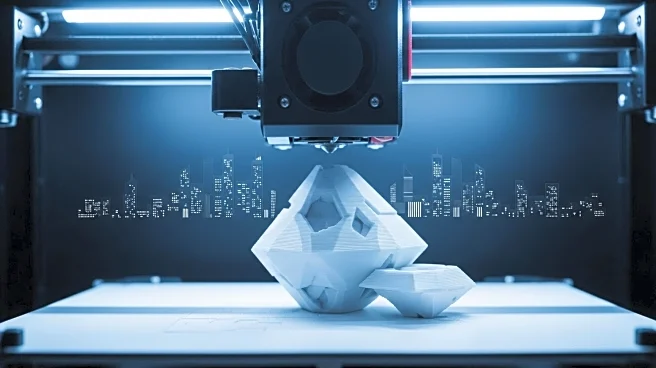

Made Smarter and Manchester Metropolitan University's PrintCity have significantly advanced 3D printing adoption in the North West of the UK, according to a study by the Department for Science, Innovation and Technology. The region boasts the highest adoption rate of 3D printing outside London, attributed to a place-based innovation model centered in Greater Manchester. Since its inception in 2019, Made Smarter North West has facilitated investments totaling £1.6 million in 3D printing technologies, supported by £442,000 in grant funding. These initiatives are projected to create 128 jobs, upskill 117 roles, and contribute £15.6 million in GVA to the local economy. The collaboration between Made Smarter and PrintCity has empowered SMEs to explore 3D printing through site visits, demonstrations, and training, fostering confidence in adopting this transformative technology.

Why It's Important?

The adoption of 3D printing technology in the North West is pivotal for regional economic growth and innovation. By enabling rapid prototyping, customization, and reducing waste, 3D printing enhances productivity across various sectors, including aerospace and healthcare. The initiative not only supports local manufacturers but also contributes to sustainable practices and technological advancement. The partnership between Made Smarter and PrintCity exemplifies how strategic collaboration can drive technological adoption, benefiting both businesses and the workforce. This development is crucial for maintaining competitive advantage and fostering a skilled labor market, which is essential for long-term economic resilience.

What's Next?

The continued collaboration between Made Smarter and PrintCity is expected to further accelerate 3D printing adoption in the region. As more SMEs gain confidence in utilizing this technology, additional investments and job creation are anticipated. The Fast Track Additive Manufacturing program will continue to upskill employees, ensuring that the workforce is equipped to handle advanced manufacturing processes. Furthermore, the Digital Technology Internship program will keep providing real-world experience to students, potentially leading to permanent employment opportunities. This ongoing support is likely to enhance the region's reputation as a hub for innovation and technological advancement.

Beyond the Headlines

The integration of 3D printing into manufacturing processes presents ethical and cultural implications, particularly in terms of sustainability and workforce dynamics. As companies adopt more efficient production methods, there may be shifts in employment patterns, requiring workers to adapt to new technologies. Additionally, the environmental benefits of reduced waste and energy consumption align with broader societal goals of sustainability. The initiative also highlights the importance of educational institutions in bridging the gap between academia and industry, fostering a culture of continuous learning and innovation.