What's Happening?

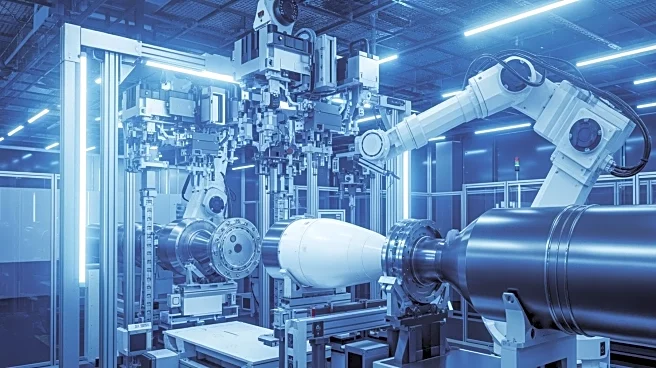

BAE Systems is enhancing its solid rocket motor (SRM) propellant production capabilities at the Radford Army Ammunition Plant in Virginia. This expansion involves the use of extrusion technology, which

is cost-effective and suitable for high-volume applications. BAE Systems aims to bridge the gap between traditional extrusion methods and modern cast-and-cure systems, which offer higher energy density and larger diameters. The company has increased the diameter of its SRMs from 2.75 inches to 8.5 inches, incorporating nitroamines to boost energy density. This development is part of BAE Systems' strategy to provide affordable and efficient solutions for tactical missile production.

Why It's Important?

The expansion of BAE Systems' SRM production capabilities is crucial for maintaining the U.S. military's readiness and technological edge. By improving the energy density and diameter of SRMs, BAE Systems can offer more powerful and versatile missile options, enhancing the effectiveness of military operations. This advancement supports national security by ensuring that the U.S. military has access to reliable and advanced weaponry. Additionally, the use of cost-effective extrusion technology allows for high-volume production, which is essential for meeting the demands of military contracts and maintaining a competitive position in the defense industry.

Beyond the Headlines

The expansion of SRM production capabilities at BAE Systems highlights the ongoing innovation within the defense sector. The integration of advanced materials and technologies into missile production reflects a broader trend towards enhancing military capabilities through technological advancements. This development may also influence other defense contractors to invest in similar technologies, potentially leading to industry-wide improvements in missile production and performance. Furthermore, the focus on cost-effective production methods underscores the importance of balancing technological innovation with budget constraints, a key consideration for defense contractors and government agencies.