What's Happening?

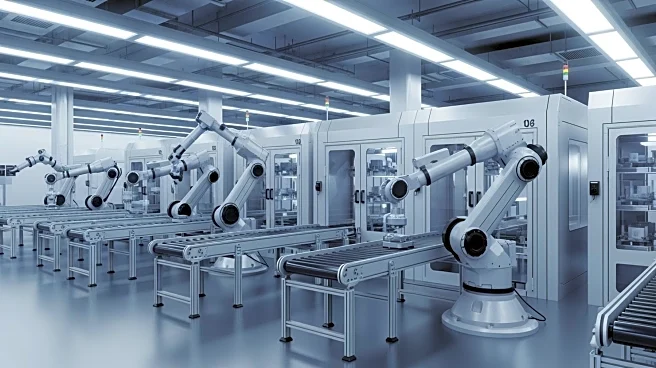

PepsiCo Polska is set to launch a new automated storage and retrieval system (AS/RS) in Grodzisk Mazowiecki, Poland, in partnership with Mecalux. This facility will utilize advanced technology to streamline

logistics operations, specifically for potato crisps and other snacks. The project includes six stacker cranes and an Automated Pallet Shuttle, connected to production lines via a floor-mounted electric monorail system and automatic conveyors. The system will operate continuously, managed by Mecalux's Easy WMS integrated with PepsiCo's SAP eWM software. This marks the third warehouse project by Mecalux for PepsiCo Polska, featuring innovations like energy recovery systems and AI-powered computer vision for precise pallet positioning.

Why It's Important?

The development of this automated warehouse is significant for PepsiCo as it aims to optimize operations, expand capacity, and reduce logistics costs. The integration of advanced technologies will enable direct deliveries, minimizing double handling and unnecessary transport. Additionally, the project is expected to reduce greenhouse gas emissions by 200 tonnes annually, aligning with sustainability goals. This move reflects a broader trend in the logistics industry towards automation and efficiency, potentially influencing other companies to adopt similar technologies to enhance their supply chain operations.

What's Next?

As PepsiCo implements this new system, it will likely monitor the efficiency gains and environmental impact closely. The success of this project could lead to further investments in automation across other facilities. Stakeholders, including logistics and technology firms, may observe PepsiCo's approach as a model for integrating advanced systems in warehouse management. The potential for reduced emissions and improved logistics efficiency may also attract attention from environmental groups and policymakers advocating for sustainable practices in industrial operations.

Beyond the Headlines

The shift towards automated warehouses raises questions about the future of employment in logistics, as automation could reduce the need for manual labor. Ethical considerations regarding job displacement and the need for workforce retraining may arise. Additionally, the reliance on AI and advanced systems highlights the importance of cybersecurity measures to protect sensitive data and ensure operational integrity. Long-term, this development could contribute to a cultural shift in how logistics operations are perceived, emphasizing technological innovation and environmental responsibility.