What's Happening?

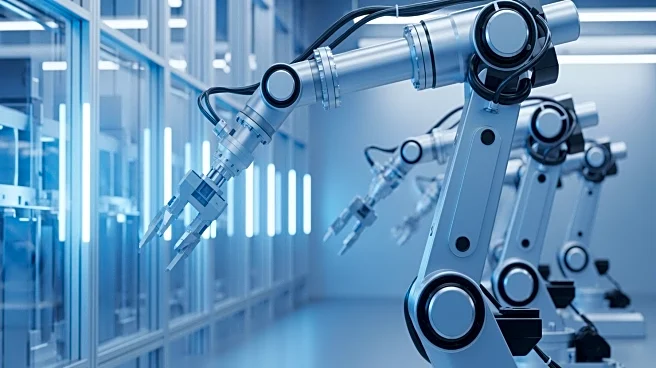

Bosch Rexroth is advancing actuator technology to meet the growing demands of industrial automation. Actuators, which convert energy into motion, are essential in automating processes across various sectors,

including medical and laboratory settings. The company is focusing on designs that accommodate longer strokes and higher payloads, enabling precision and speed in large-scale, high-throughput automation. This innovation is particularly transformative in medical applications, where actuators are used in systems ranging from compact analyzers to room-sized testing environments capable of handling numerous samples simultaneously. The modularity, scalability, and reliability of these actuators provide a roadmap for engineers aiming to enhance automation in other manufacturing sectors.

Why It's Important?

The advancements in actuator technology by Bosch Rexroth are significant for the industrial sector, as they promise increased efficiency and precision in automation processes. This is crucial for industries that rely on high-throughput systems, such as healthcare and manufacturing, where the ability to handle large volumes of work quickly and accurately can lead to improved productivity and reduced operational costs. The scalability and reliability of these actuators also mean that they can be adapted to various applications, potentially leading to innovations in other fields. Companies that integrate these advanced actuators into their systems may gain a competitive edge by optimizing their operations and enhancing their service delivery.

What's Next?

As Bosch Rexroth continues to develop and refine its actuator technology, industries are likely to see further integration of these components into their automation systems. This could lead to new applications and improvements in existing processes, particularly in sectors that require precise and efficient handling of materials. Stakeholders in manufacturing and healthcare may explore partnerships or investments to leverage these advancements, potentially leading to collaborative efforts to push the boundaries of automation technology. Additionally, ongoing research and development may result in even more sophisticated actuator designs, further expanding their utility across different industries.

Beyond the Headlines

The evolution of actuator technology not only impacts industrial efficiency but also raises questions about the future of labor in automated environments. As automation becomes more prevalent, there may be shifts in workforce dynamics, requiring new skills and training for employees to manage and maintain these advanced systems. Furthermore, the ethical implications of automation in sensitive areas like healthcare, where human oversight is crucial, must be considered. Balancing technological advancement with ethical standards will be essential as industries continue to adopt these innovations.