What's Happening?

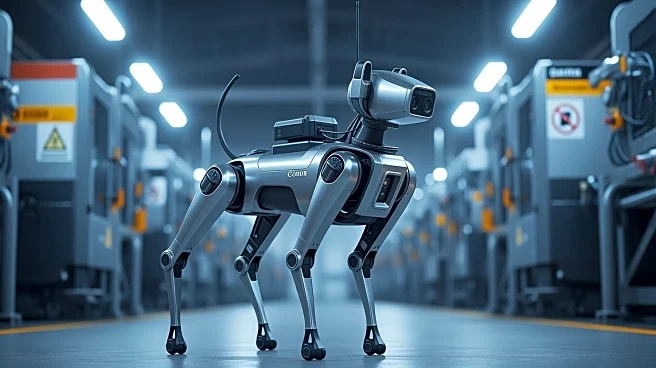

Cargill has introduced a robotic dog named Spot, developed by Boston Dynamics, to patrol its multiseed crush and refinery plant. Spot is equipped with advanced sensors that collect real-time thermal, acoustic,

and visual data, performing up to 10,000 inspections weekly without fatigue. The robot identifies potential issues such as overheating equipment and product leaks, and also checks for safety hazards like open doors and blocked walkways. This automation allows employees to focus on analysis and decision-making tasks.

Why It's Important?

The deployment of Spot represents a significant step towards automation in industrial operations, enhancing safety and efficiency. By using robotics, Cargill can reduce human error and increase the reliability of its inspections, potentially lowering maintenance costs and preventing accidents. This move also highlights the growing role of AI and robotics in transforming traditional manufacturing processes, paving the way for more resilient and sustainable operations.

What's Next?

Cargill is evaluating the potential to scale Spot's use across its European network, indicating a shift towards predictive, digital-first plant management. This pilot project could lead to broader adoption of robotics and AI in the food industry, influencing how companies approach safety and efficiency in their operations.