What's Happening?

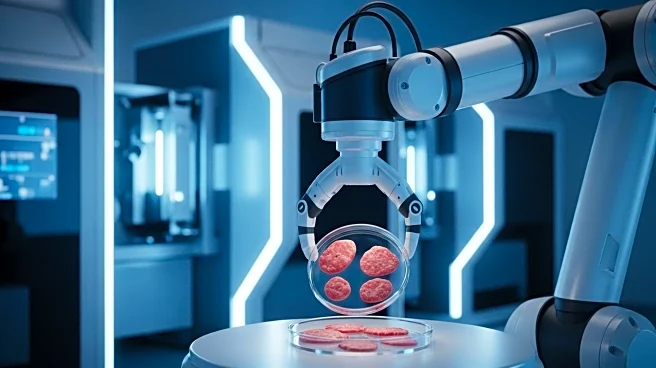

A San Francisco-based cell-cultured meat pilot plant is making significant strides towards lights-out manufacturing, a process where production is fully automated and requires minimal human intervention. The facility has implemented rugged mobile kits with historian software to capture over 100 PLC tags, enabling remote monitoring and real-time visualization of critical parameters such as temperature, pH, and dissolved oxygen during 28-day production runs. This advancement allows for higher uptime, tighter process control, reduced manual interventions, and lower energy consumption, moving closer to cost parity with conventional seafood while maintaining quality standards. The initiative, led by Lucid Automation and Security, began as a study to validate real-time data capture and remote visualization strategies, ultimately pushing the plant towards a more autonomous operation.

Why It's Important?

The move towards lights-out manufacturing in the cultured meat industry represents a significant shift in production efficiency and sustainability. By reducing the need for human intervention, the facility can lower operational costs and energy consumption, which is crucial for achieving cost parity with traditional meat products. This development could accelerate the adoption of cultured meat, offering a more sustainable alternative to conventional meat production, which is often criticized for its environmental impact. The automation of cell cultivation not only supports the company's sustainability goals but also ensures compliance with quality standards, potentially setting a precedent for other facilities in the industry.

What's Next?

As the facility continues to refine its automation processes, it is likely to explore further integration of advanced technologies to enhance production efficiency. The success of this pilot plant could encourage other cultured meat producers to adopt similar strategies, potentially leading to broader industry shifts towards automation. Stakeholders, including investors and environmental advocates, may closely monitor these developments, as they could influence future investments and regulatory considerations in the cultured meat sector.

Beyond the Headlines

The transition to lights-out manufacturing raises questions about the future role of human workers in the industry. While automation can lead to job displacement, it also creates opportunities for new roles focused on overseeing and maintaining automated systems. Additionally, the ethical implications of cultured meat production, such as animal welfare and environmental sustainability, may gain more attention as the industry evolves.