What's Happening?

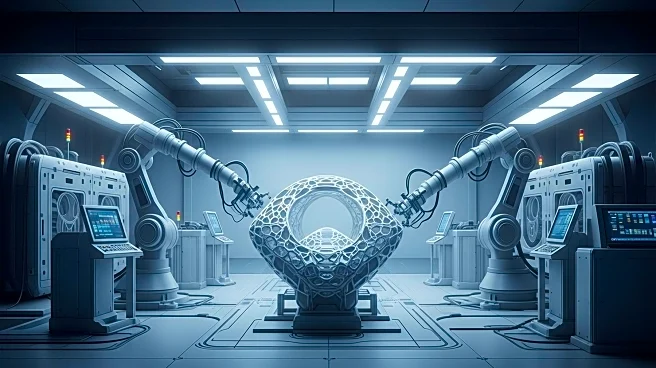

CT UAV has announced the development of a self-evolving composite molding plant, designed to produce advanced composite materials for UAVs. The plant, located in Ho Chi Minh City, Vietnam, is equipped with state-of-the-art technology for molding fuselages, wings, propellers, and other aircraft parts. The facility emphasizes the use of next-generation materials and advanced manufacturing processes to enhance UAV production.

Why It's Important?

The establishment of a self-evolving composite molding plant represents a significant advancement in UAV manufacturing. By utilizing advanced composite materials and automated processes, CT UAV aims to improve the performance and efficiency of its UAVs. This development positions the company as a leader in the aerospace industry and highlights the potential for innovation in UAV technology.

What's Next?

CT UAV plans to continue expanding its manufacturing capabilities and exploring new applications for its advanced composite materials. The company aims to leverage its technology to produce a wide range of UAV components, from engines to batteries. As the plant evolves, CT UAV will likely focus on further integrating AI and automation to enhance production efficiency and quality.

Beyond the Headlines

The use of advanced composite materials in UAV manufacturing raises questions about sustainability and environmental impact. As the aerospace industry continues to innovate, companies must consider the long-term implications of their manufacturing processes and materials on the environment.