What's Happening?

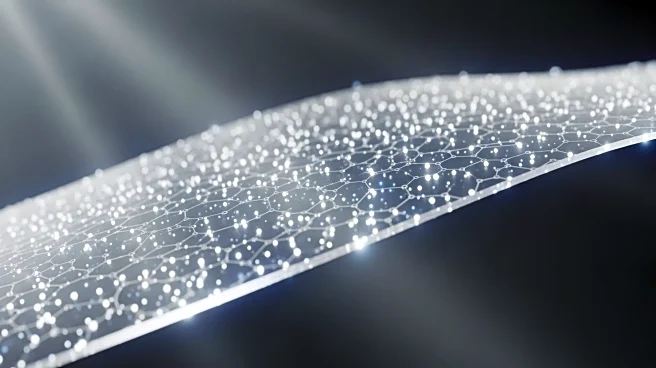

Researchers at Virginia Tech have developed an AI-powered system to monitor wire-arc additive manufacturing, a process akin to 3D welding. This system detects and corrects flaws in real-time, ensuring parts are ready for use upon completion. The technology promises to revolutionize the production of complex components for submarines and aircraft, offering a faster and less wasteful alternative to traditional machining methods.

Why It's Important?

The integration of AI in additive manufacturing represents a significant leap forward in the efficiency and reliability of metal production. By reducing waste and production time, this technology can lower costs and improve the availability of critical components for defense and aerospace industries. The advancement supports the modernization of manufacturing processes and enhances the competitiveness of U.S. industries.

What's Next?

The research team plans to further refine the AI algorithms and explore additional applications of the technology. As the system is adopted more widely, it could lead to broader changes in manufacturing practices and supply chain management.