What is the story about?

What's Happening?

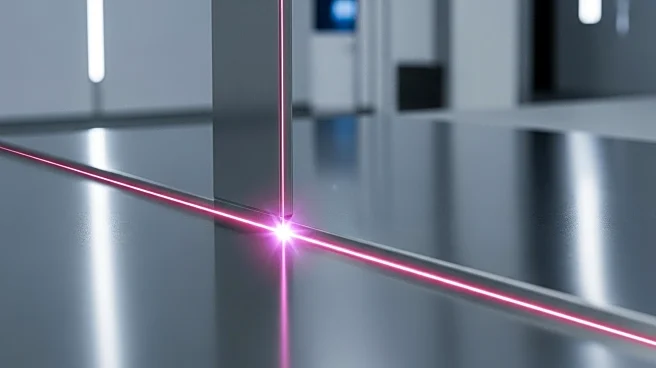

A recent study has demonstrated that strong-field laser surface passivation can significantly reduce the corrosion of stainless steel. The research involved treating various stainless steel samples, including AISI 304, with a commercial Ti: Sapphire laser system. This process involved a linearly polarized laser pulse train with a central wavelength of 800 nm, which was focused to create a single filament. The laser-treated samples showed improved corrosion resistance in saline, acidic, and alkaline environments, with corrosion rates reduced by 3-6 orders of magnitude compared to untreated samples. The study utilized electrochemical measurements to assess the corrosion performance, revealing that the laser-treated surfaces exhibited significantly lower corrosion current densities.

Why It's Important?

This advancement in laser surface passivation technology holds significant implications for industries reliant on stainless steel, such as construction, automotive, and aerospace. By enhancing the corrosion resistance of stainless steel, the technology could extend the lifespan of steel components, reduce maintenance costs, and improve safety. The reduction in corrosion rates also suggests potential environmental benefits, as it could decrease the frequency of steel replacement and the associated resource consumption. Industries that face harsh environmental conditions, such as marine and chemical processing, stand to gain considerably from this technology, as it offers a more durable and cost-effective solution for protecting steel infrastructure.

What's Next?

Further research and development are likely to focus on optimizing the laser treatment process for different types of stainless steel and other metals. There may also be efforts to scale the technology for industrial applications, ensuring it is cost-effective and practical for widespread use. Stakeholders in the steel manufacturing and processing industries may explore partnerships or investments to integrate this technology into their production lines. Additionally, regulatory bodies might consider updating standards and guidelines to incorporate new corrosion resistance technologies, potentially influencing industry practices and policies.

Beyond the Headlines

The use of laser technology for surface passivation could lead to broader applications beyond corrosion resistance. This method might be adapted for other surface modifications, such as enhancing wear resistance or altering surface properties for specific industrial applications. The development of such technologies could also stimulate innovation in laser processing techniques, potentially leading to new discoveries in material science and engineering. Furthermore, the environmental benefits of reduced corrosion could contribute to sustainability goals, aligning with global efforts to minimize industrial waste and resource consumption.