What's Happening?

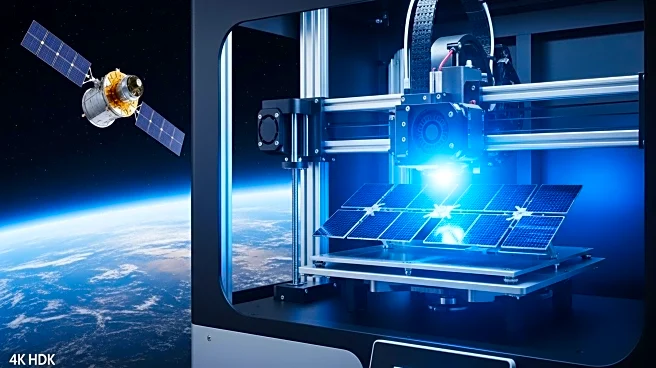

Boeing has announced the use of 3D printing for the structural panels of satellite solar arrays, aiming to cut production times in half and meet the demand for faster spacecraft deployment. The first 3D-printed arrays will feature Spectrolab solar cells on small satellites built by Millennium Space Systems, subsidiaries of Boeing's Space Mission Systems division. This new manufacturing process reduces the timeline by about six months from print to final assembly, representing a production improvement of up to 50%. The approach allows for parallel assembly of arrays with cell production, utilizing robot-assisted assembly and automated inspection to enhance speed and consistency.

Why It's Important?

The adoption of 3D printing in satellite manufacturing by Boeing signifies a major shift towards more efficient production methods in the aerospace industry. This innovation could lead to faster deployment of satellite constellations, benefiting sectors such as telecommunications, defense, and scientific research. By reducing production times and costs, Boeing enhances its competitive position in the global aerospace market, potentially influencing other companies to adopt similar technologies. The integration of additive manufacturing reflects a broader trend in the industry towards leveraging advanced technologies to improve performance and reduce lead times.

What's Next?

Boeing plans to scale its 3D printing technology across its satellite platforms, targeting market availability by 2026. The company is expected to further integrate this technology into its production lines, potentially leading to more widespread adoption across the aerospace sector. As Boeing progresses through its standard qualification path, the successful implementation of this technology could prompt other aerospace companies to explore similar innovations, driving industry-wide advancements in satellite manufacturing.