What's Happening?

Digital twins are increasingly being recognized for their potential to improve complex manufacturing processes, as highlighted by Sergey Kostantantinov, Automation Project Manager at Samworth Brothers.

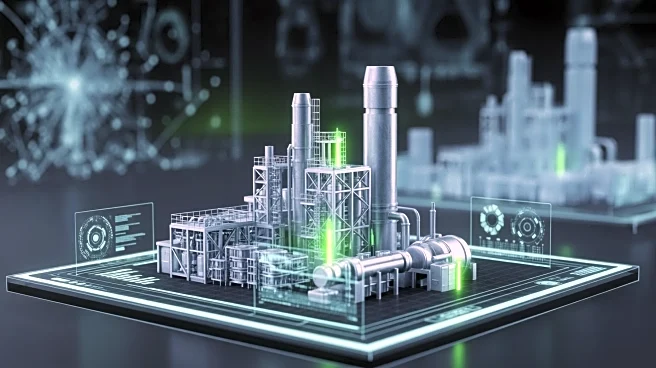

During the Manufacturing Leaders’ Summit, Kostantantinov discussed how digital twins can streamline production by making processes easier and less costly to test and plan. This technology allows for the creation of a virtual model of a physical process, enabling manufacturers to simulate and optimize operations before implementing changes in the real world. The summit will feature further discussions on the role of digital twins in manufacturing.

Why It's Important?

The adoption of digital twins in manufacturing represents a significant shift towards more efficient and cost-effective production methods. By allowing companies to simulate and refine processes virtually, digital twins can reduce the risk of errors and the costs associated with physical testing. This technology is particularly valuable in industries where precision and efficiency are critical. As more manufacturers adopt digital twins, the industry could see a reduction in production costs and an increase in innovation, potentially leading to more competitive pricing and improved product quality for consumers.

What's Next?

As digital twins gain traction, more manufacturers are likely to explore their potential applications. The ongoing discussions at the Manufacturing Leaders’ Summit suggest that industry leaders are keen to understand and leverage this technology. Future developments may include broader adoption across various sectors, increased investment in digital twin technology, and further integration with other digital transformation initiatives. Stakeholders, including technology providers and manufacturing companies, will need to collaborate to address challenges such as data integration and cybersecurity.

Beyond the Headlines

The rise of digital twins also raises questions about workforce implications, as automation and digital processes could alter job roles within manufacturing. Companies may need to invest in training and upskilling employees to work alongside advanced technologies. Additionally, the ethical considerations of data privacy and security in digital twin applications will require careful management to ensure compliance with regulations and protect sensitive information.