What's Happening?

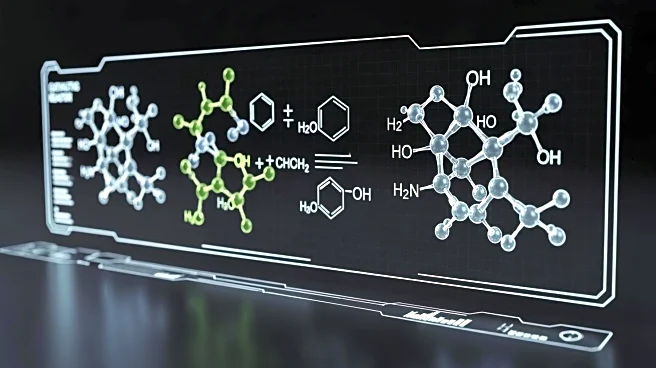

Victor Sans and collaborators have introduced a digital platform that integrates the design, fabrication, and optimization of catalytic reactors using machine learning and 3D printing. This platform was

tested on two multiphasic reactions: the hydrogenation of acetophenone and the CO2 cycloaddition to epoxides. The reactors optimized for these reactions have different structures but achieve excellent space-time yield. The platform combines geometric design and precise control of reaction conditions, enhancing catalytic performance and saving researchers' time.

Why It's Important?

This platform represents a significant advancement in the field of chemical engineering, particularly in the design and optimization of catalytic reactors. By utilizing machine learning and 3D printing, researchers can achieve more efficient and effective reactor designs, potentially leading to breakthroughs in chemical synthesis and production. The ability to tailor reactor designs to specific reactions could improve yields and reduce costs, benefiting industries that rely on complex chemical processes. This innovation also highlights the growing role of digital technologies in scientific research and development.

What's Next?

The platform may be expanded to include more complex reactions and further optimize reactor designs. Researchers could explore additional applications in various chemical processes, potentially leading to new industrial standards. The integration of machine learning and 3D printing in reactor design might inspire similar innovations in other fields, promoting interdisciplinary collaboration. Industries could begin adopting this technology to enhance their production capabilities and efficiency.

Beyond the Headlines

The use of digital platforms in chemical research raises questions about the future of traditional experimental methods and the role of automation in scientific discovery. Ethically, the technology could democratize access to advanced research tools, allowing smaller institutions to compete with larger entities. The platform's ability to optimize reactor designs might lead to more sustainable chemical processes, aligning with global efforts to reduce environmental impact.