What's Happening?

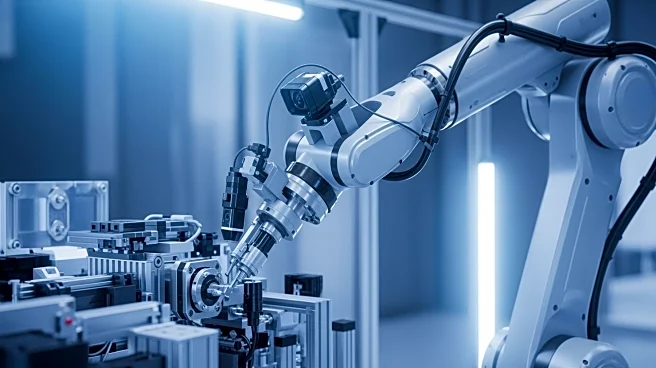

AgiBot has successfully deployed its Real-World Reinforcement Learning (RW-RL) system in a manufacturing pilot with Longcheer Technology. This marks the first application of RW-RL on an active production line, connecting advanced AI innovation with large-scale

production. The system addresses challenges in flexible manufacturing by enabling robots to learn and adapt directly on the factory floor. AgiBot's RW-RL system allows robots to acquire new skills within minutes, maintain long-term performance, and adapt to changes with minimal hardware adjustments. This development signifies a critical step in the evolution of intelligent automation for precision manufacturing.

Why It's Important?

The deployment of AgiBot's RW-RL system represents a significant advancement in manufacturing technology, potentially transforming the industry by reducing the time and cost associated with reconfiguring production lines. This system enhances flexibility and efficiency, allowing for rapid adaptation to changes in product design or production requirements. The ability to quickly retrain robots without custom fixtures or tooling addresses the long-standing dilemma of rigid automation versus variable demand, particularly in consumer electronics manufacturing. This innovation could lead to increased competitiveness and productivity in U.S. manufacturing sectors, benefiting companies that adopt such advanced technologies.

What's Next?

AgiBot and Longcheer plan to expand the application of real-world reinforcement learning to a broader range of precision manufacturing scenarios, including consumer electronics and automotive components. The focus will be on developing modular, rapidly deployable robot solutions that integrate seamlessly with existing production systems. This expansion could further enhance the adaptability and efficiency of manufacturing processes, potentially leading to wider adoption of AI-driven automation in various industries.

Beyond the Headlines

The integration of RW-RL systems in manufacturing could have broader implications for the workforce, as it may shift the role of human workers from manual tasks to more supervisory and maintenance roles. This technological shift could necessitate new training programs and educational initiatives to equip workers with the skills needed to manage and collaborate with advanced robotic systems. Additionally, the deployment of such systems raises ethical and legal considerations regarding data privacy and the potential displacement of jobs, which will need to be addressed as the technology becomes more widespread.