What's Happening?

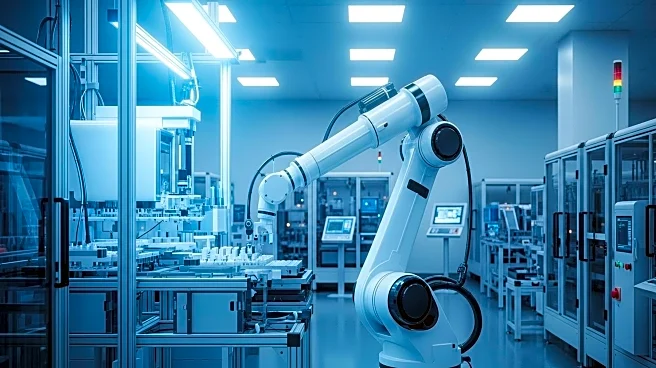

The pharmaceutical manufacturing industry is increasingly adopting artificial intelligence (AI) to address challenges such as production inflexibility, quality control complexities, and supply chain vulnerabilities. A new white paper by Zühlke and the University of St. Gallen outlines the potential of AI to transform manufacturing processes, making them more efficient and reliable. The paper provides a framework for implementing AI in GxP-regulated environments, highlighting case studies from leading pharmaceutical companies. The industry faces regulatory complexities and workforce limitations, making AI adoption not just an opportunity but a necessity for competitive advantage.

Why It's Important?

AI's integration into pharmaceutical manufacturing is crucial for enhancing efficiency and resilience in the face of global disruptions and regulatory changes. By automating quality control and optimizing resource management, AI can significantly reduce operational costs and improve product quality. This transformation is vital for pharmaceutical companies to remain competitive and meet the growing demand for innovative and reliable healthcare solutions. The insights from the white paper can guide industry professionals in successfully implementing AI, potentially leading to widespread industry transformation.

What's Next?

Zühlke will host a panel discussion at the World Health Summit in Berlin, focusing on how pharmaceutical manufacturing can remain resilient amid geopolitical instability and rapid technological change. This event will bring together global health and industry experts to explore AI's role in future-proofing production processes. As AI becomes integral to manufacturing, companies will need to invest in technology and workforce training to fully leverage its benefits. The ongoing dialogue and research will likely drive further innovations and collaborations in the sector.