What is the story about?

What's Happening?

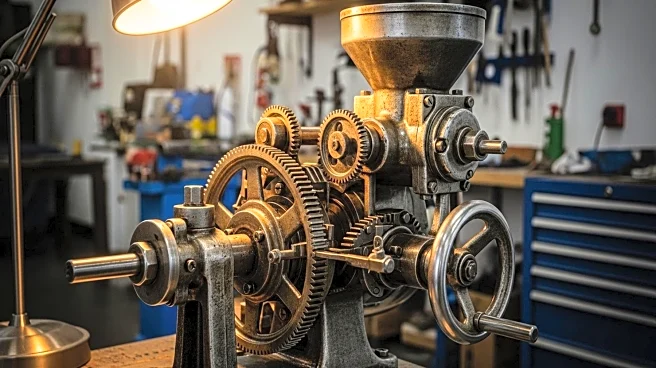

BEP Surface Technologies, a specialist in electroplating and surface finishing, is undertaking a significant project to upgrade a 70-year-old Churchill TWR roll grinder. The project, valued at nearly $805,000, aims to transform the machine into a state-of-the-art precision engineering tool. In collaboration with Siemens and Made Smarter, the grinder is receiving a complete mechanical and electrical overhaul to achieve tolerances as fine as 0.001 mm. This refurbishment, currently 30% complete, is expected to expand BEP's capacity and capability, allowing the company to produce ultra-precise finishes for sectors such as electric vehicle batteries and carbon fiber manufacturing. The upgrade includes the installation of Siemens SINUMERIK One CNC control, servo motors, and a SINAMICS S120 drive system, enhancing the machine's precision and traceability.

Why It's Important?

The upgrade of the Churchill TWR roll grinder is crucial for BEP Surface Technologies as it addresses a significant market gap in the UK. By achieving tighter tolerances, BEP can attract new business and retain existing customers who require ultra-precise rollers for packaging and carbon fiber production. This project not only strengthens BEP's capabilities but also contributes to reshoring critical manufacturing capabilities to the UK, reducing costs, shortening lead times, and cutting carbon emissions. The investment is expected to bolster UK supply chains and enhance competitiveness in fast-growing sectors like electric vehicle batteries and composites.

What's Next?

As the refurbishment project progresses, BEP Surface Technologies anticipates completing the upgrade within two years. The integration work, carried out by Machine Code Engineering, includes sourcing, installing, and programming the Siemens system, along with providing operator training. Once completed, BEP expects to secure new business opportunities and enhance its service offerings. The upgraded machine will enable BEP to accept work previously turned away due to precision limitations, thereby expanding its market reach and customer base.

Beyond the Headlines

The transformation of the Churchill TWR roll grinder represents a broader trend in the manufacturing industry towards digital technology adoption and precision engineering. By investing in advanced machinery and technology, BEP Surface Technologies is setting a precedent for other companies in the sector to follow. This move not only enhances BEP's competitive edge but also contributes to the UK's industrial growth and innovation, positioning the country as a leader in precision engineering.