What's Happening?

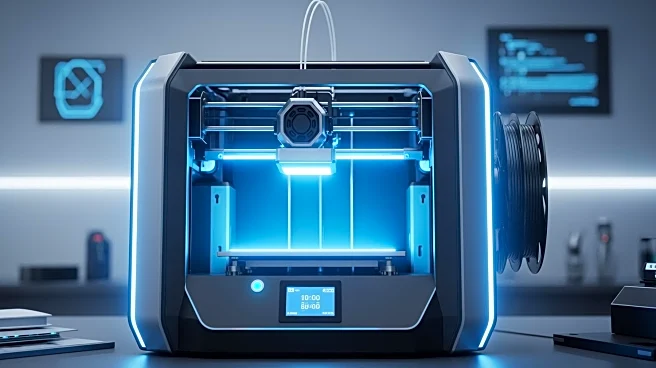

Researchers have developed a new method for 3D printing metallic materials using a composite system of aluminum and copper(II) oxide. This approach eliminates the need for traditional sintering and melting

processes that require external heat sources. The technology leverages a self-propagating reaction to produce molten metal, which can then be used to create complex 3D structures. This innovation represents a significant advancement in the field of additive manufacturing, offering a more efficient and flexible method for producing metal components.

Why It's Important?

This development could revolutionize the additive manufacturing industry by reducing the complexity and cost associated with traditional 3D printing methods. By eliminating the need for external heat sources, the process becomes more energy-efficient and environmentally friendly. It also allows for greater flexibility in the types of materials that can be used, potentially leading to the creation of new alloys and composites with enhanced properties. This could benefit industries such as aerospace, automotive, and electronics, where high-performance materials are in demand.

What's Next?

The next steps for this technology include further refinement and testing to ensure its scalability and reliability for industrial applications. Researchers may explore the potential for using this method to print other types of metals and composites, expanding its applicability across various sectors. Additionally, collaborations with industry partners could facilitate the integration of this technology into existing manufacturing processes, accelerating its adoption and impact.

Beyond the Headlines

The introduction of this technology could lead to a shift in the manufacturing landscape, with implications for supply chains and labor markets. As the need for traditional metalworking skills decreases, there may be a growing demand for expertise in digital design and materials science. Furthermore, the environmental benefits of reducing energy consumption and waste could contribute to more sustainable manufacturing practices.