What is the story about?

What's Happening?

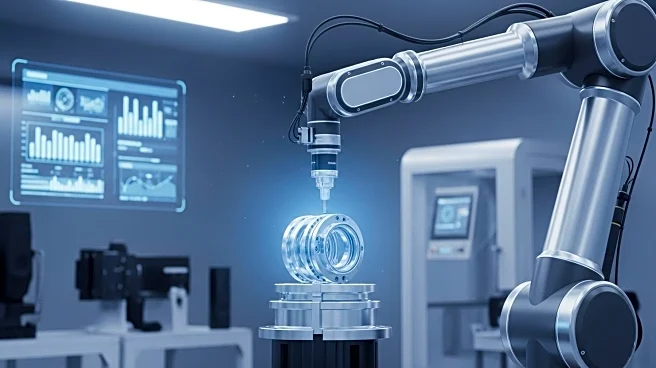

Manufacturers are increasingly integrating artificial intelligence into their quality management systems to enhance efficiency and compliance. The shift from reactive to predictive quality management is driven by the need to address real-time operational demands and evolving regulatory expectations. AI is being utilized for pattern recognition in non-conformance data, predictive maintenance scheduling, automated compliance monitoring, and intelligent workflow routing. Forward-thinking manufacturers are strategically building capabilities on modern system architecture to support AI integration, ensuring their quality processes are future-proofed against regulatory changes. The upcoming Ideagen digital summit will further explore these topics.

Why It's Important?

The integration of AI in quality management represents a significant transformation in the manufacturing industry. By moving beyond compliance as a checkbox exercise, manufacturers can leverage AI to predict issues before they escalate, turning compliance data into a competitive advantage. This approach not only enhances operational efficiency but also prepares businesses for future regulatory changes. As regulatory frameworks evolve, manufacturers that proactively adapt their quality systems will be better positioned to meet new standards and maintain market leadership. The strategic use of AI in quality management can drive innovation and improve product quality, benefiting both manufacturers and consumers.

What's Next?

Manufacturers are preparing for upcoming regulatory changes, including revisions to ISO 9001 and evolving expectations from the FDA and EMA. By building flexible quality systems that can accommodate regulatory change, businesses can avoid costly system replacements and ensure compliance. The Ideagen 'Beyond the Horizon' digital summit on October 21st will provide further insights into these developments, offering manufacturers the opportunity to explore strategies for future-proofing their quality management processes. As AI continues to transform the industry, manufacturers must remain vigilant in adapting their systems and practices to stay ahead of regulatory and technological advancements.

Beyond the Headlines

The integration of AI in quality management raises important ethical and practical considerations. Manufacturers must ensure that AI-driven decisions are validated and maintain human oversight to uphold quality standards. The balance between speed and quality rigour is crucial, as faster innovation cycles must not compromise thoroughness. Additionally, the shift towards AI-powered systems may impact workforce dynamics, requiring new skills and roles. As manufacturers navigate these changes, they must prioritize responsible AI implementation, ensuring that their quality management systems are both effective and ethical.