What's Happening?

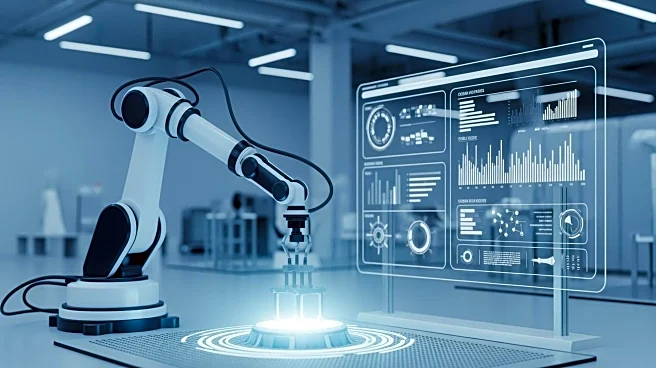

Technology is playing a transformative role in the manufacturing industry by enhancing productivity through automation and software solutions. Automation technologies, such as robotics, are streamlining

processes, reducing human error, and improving product quality. Software solutions for scheduling, inventory management, and workflow monitoring are helping manufacturers optimize operations and reduce time-to-market. These advancements are leading to higher efficiency, lower production costs, and improved safety standards. As businesses seek to improve efficiency and productivity, technology is proving to be a game-changer in the manufacturing sector.

Why It's Important?

The integration of technology in manufacturing is crucial for companies to remain competitive in a fast-paced and globalized market. Automation and software solutions can significantly reduce operational costs, enhance product quality, and improve safety standards, thereby driving profitability and growth. As manufacturers face challenges such as labor shortages and supply chain disruptions, technology offers a strategic advantage by enabling more efficient and agile operations. The adoption of technology also reflects broader trends in digital transformation and the shift towards more sustainable and innovative manufacturing practices.

What's Next?

Manufacturers are expected to continue investing in technology to further enhance productivity and operational efficiency. This may involve expanding the use of automation and software solutions across various aspects of the manufacturing process, from production to logistics. Companies will also need to address challenges related to data management and cybersecurity to fully leverage the benefits of technology. As the manufacturing sector evolves, businesses will likely explore new opportunities for innovation and collaboration to drive growth and adapt to changing market conditions.

Beyond the Headlines

The increasing reliance on technology in manufacturing may have broader implications for the workforce, as automation can lead to shifts in employment patterns and skill requirements. Companies may need to invest in training and development programs to equip workers with the skills needed to operate and collaborate with advanced technologies. Additionally, the integration of technology may influence global trade dynamics, as companies seek to optimize production processes and reduce reliance on international supply chains.