What's Happening?

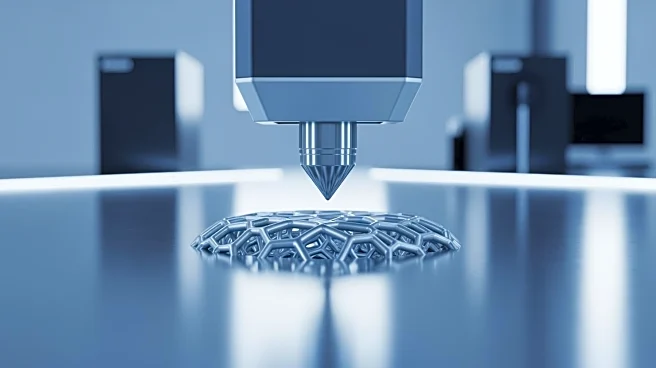

Renishaw is showcasing its latest advancements in additive manufacturing (AM) at Formnext 2025 in Frankfurt, Germany. The company is presenting a production-focused exhibit under the theme 'From Print

to Precision: Productivity Upgraded,' highlighting high-productivity AM workflows. Central to this showcase is LIBERTAS, a new software that optimizes laser parameter tuning, addressing challenges such as poor downskin surface finish and the need for support structures. Renishaw's exhibit includes a new long-life filtration system for its RenAM 500 series, designed to enhance machine uptime and reduce costs. The showcase also features advanced microturbines from Argive, demonstrating the potential of AM in propulsion applications.

Why It's Important?

Renishaw's innovations in additive manufacturing are poised to significantly impact industries reliant on precision engineering, such as aerospace and energy. By improving surface finishes and reducing the need for support structures, LIBERTAS enhances the efficiency and quality of AM processes, potentially lowering production costs and waste. The introduction of a long-life filtration system further supports continuous production, crucial for high-demand environments. These advancements could drive broader adoption of AM technologies, influencing manufacturing practices and competitive dynamics in sectors that prioritize high-performance components.

What's Next?

Renishaw's collaboration with Siemens Digital Industries Software to showcase integrated AM workflows suggests future developments in digital twin technologies and precision manufacturing. This partnership may lead to new standards in certifiable parts production for aerospace and defense applications. As Renishaw continues to innovate, stakeholders in manufacturing and technology sectors may explore similar integrations, potentially leading to new business models and partnerships. The ongoing evolution of AM technologies could also prompt regulatory bodies to update standards and certifications, ensuring safety and reliability in advanced manufacturing processes.