What's Happening?

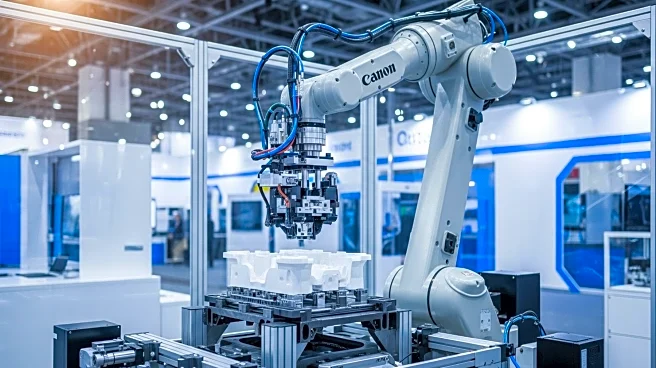

Shibaura Machine, a leader in industrial automation and injection moulding, is presenting its latest robotic solutions at the K Show 2025, the largest plastics and rubber trade fair globally. The company is demonstrating a fully automated production cell featuring the TVM900 6-axis robot integrated with the EC75SXIII injection moulding machine. This setup will produce plastic business card cases in real-time, highlighting the efficiency and precision of their technology. The SXIII series, known for its energy-efficient operation, includes 16 models with varying tonnage requirements, all equipped with the V70 controller for optimized cycle times. The TVM900 robot, with a 900 mm reach and 20 kg payload capacity, offers rapid motion control and high repeatability. Additionally, the RoboPrint printing head will transfer logos onto moulded parts, showcasing the potential for robotic integration in manufacturing.

Why It's Important?

The integration of robotics in injection moulding represents a significant advancement in manufacturing technology, offering increased efficiency and precision. By automating tasks such as part handling and quality control, manufacturers can meet growing demand while ensuring consistent product quality. This technological shift promises faster returns on investment and positions Shibaura Machine as a key player in the industry. The company's commitment to energy-efficient and reliable solutions aligns with broader industry trends towards sustainability and operational excellence. As manufacturers seek to enhance productivity and reduce costs, Shibaura's innovations could lead to widespread adoption of robotic systems in plastics manufacturing.

What's Next?

Shibaura Machine's participation in the K Show 2025 provides an opportunity for industry stakeholders to witness the future of robotics and injection moulding firsthand. The event, running from October 8 to 15 in Düsseldorf, will allow potential clients and partners to engage directly with the TM Robotics team and explore collaboration opportunities. As the industry continues to evolve, Shibaura's advancements may influence other manufacturers to adopt similar technologies, potentially reshaping the landscape of plastics production. The company's focus on complete solutions for the sector suggests ongoing developments and potential expansions in their product offerings.

Beyond the Headlines

The integration of robotics in manufacturing not only enhances efficiency but also raises questions about the future workforce in the industry. As automation becomes more prevalent, there may be shifts in employment patterns, requiring workers to adapt to new roles focused on managing and maintaining robotic systems. Additionally, the emphasis on energy efficiency and precision aligns with global sustainability goals, potentially influencing regulatory standards and industry practices. Shibaura Machine's innovations could serve as a model for other sectors seeking to balance technological advancement with environmental responsibility.