What's Happening?

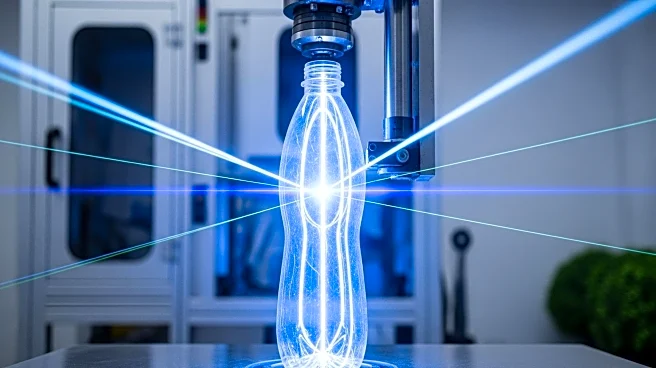

Sidel has unveiled a new laser-powered PET blowing technology, marking a significant advancement in the production of PET bottles. This innovation promises to enhance efficiency, quality, and sustainability in the beverage industry. The laser technology replaces traditional halogen heating methods, offering precise control over material thickness and enabling lightweighting opportunities. This development comes as producers face increasing pressure to reduce costs and improve sustainability. The laser-powered ovens are ready for use without the need for heating or cooling time, reducing downtime and improving line efficiency.

Why It's Important?

The introduction of laser-powered PET technology could revolutionize the beverage packaging industry by significantly reducing energy consumption and material waste. This advancement aligns with global sustainability goals and could lead to cost savings for manufacturers. The ability to produce lighter bottles without compromising structural integrity may also reduce transportation costs and carbon emissions. As the industry moves towards more sustainable practices, this technology could set new standards and drive further innovation in packaging solutions.

What's Next?

Sidel's laser-powered technology is already being used commercially in Europe, and its adoption is expected to grow as more companies seek sustainable solutions. The industry will likely monitor the performance and benefits of this technology closely, potentially leading to wider implementation across different sectors. As the technology proves its value, it may encourage further research and development in laser applications for other manufacturing processes.

Beyond the Headlines

The shift to laser-powered technology highlights the ongoing transformation in manufacturing towards more sustainable practices. This development may influence regulatory standards and consumer expectations, pushing companies to adopt greener technologies. The precision and efficiency of laser technology could also inspire innovations in other industries, such as automotive and electronics, where material efficiency is crucial.