What's Happening?

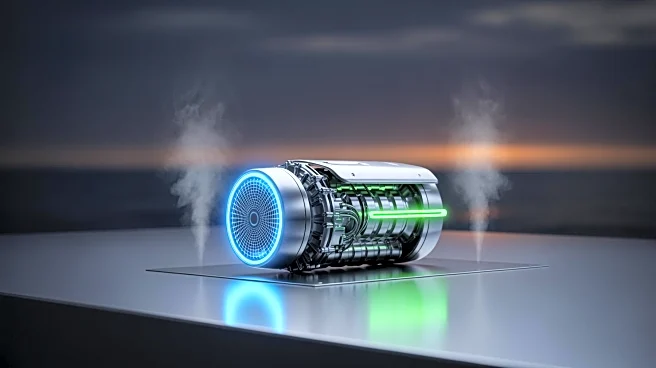

A cultured meat facility in San Francisco is making strides toward lights-out manufacturing, a process where production runs with minimal human intervention. The facility has deployed rugged mobile kits with historian software to capture over 100 PLC tags, enabling remote monitoring and real-time visualization of critical parameters such as temperature, pH, and dissolved oxygen during production. This automation allows for higher uptime, tighter process control, and reduced manual interventions, moving closer to cost parity with conventional seafood while maintaining quality standards.

Why It's Important?

The move toward automated manufacturing in the cultured meat industry represents a significant step in achieving sustainability and efficiency. By reducing the need for human intervention, the facility can lower energy consumption and operational costs, making cultured meat more competitive with traditional meat products. This advancement supports the industry's strategic vision for sustainability and could accelerate the adoption of cultured meat as a viable alternative to conventional meat, addressing environmental and ethical concerns associated with traditional meat production.

What's Next?

The facility plans to continue enhancing its automation capabilities, aiming for a fully autonomous manufacturing model. This involves further integration of remote monitoring systems and data visualization tools to support quality compliance and process optimization. As the industry progresses, other cultured meat producers may adopt similar technologies, potentially leading to widespread changes in meat production practices. Stakeholders, including investors and environmental groups, are likely to monitor these developments closely, as they could influence market dynamics and regulatory frameworks.

Beyond the Headlines

The shift toward automated manufacturing in cultured meat production highlights broader trends in the food industry, where technology is increasingly used to improve efficiency and sustainability. This development may prompt discussions on the ethical implications of automation and its impact on employment in the sector. Additionally, the focus on reducing energy consumption aligns with global efforts to combat climate change, positioning cultured meat as a key player in sustainable food production.