What's Happening?

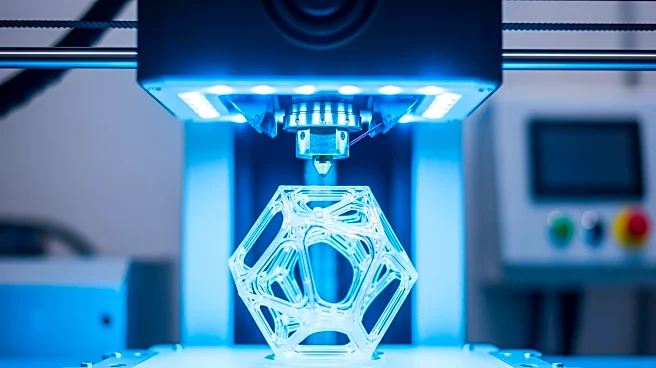

INTAMSYS, a leader in industrial FFF 3D printing, has launched its latest high-performance materials 3D printer, the FUNMAT PRO 310 APOLLO, at the Formnext event in Frankfurt, Germany. This new printer is designed to enhance continuous production capabilities

using PAEK materials, marking a significant advancement in the field of industrial additive manufacturing. The FUNMAT PRO 310 APOLLO offers up to four times faster print speeds and over twice the Z-axis strength compared to previous models, thanks to its unique multi-physics process control and optimization. It includes features such as dual 3kg active-drying filament boxes, RFID material recognition, and the INTAMQualityTM traceability system, which ensures process stability and production consistency. The INTAMSUITE NEOTM slicing platform further supports intelligent path planning and process adaptation, providing precise control over temperature, flow, and path for reliable high-performance material prints.

Why It's Important?

The launch of the FUNMAT PRO 310 APOLLO represents a pivotal shift in the industrial 3D printing landscape, particularly for sectors requiring high-performance materials like aerospace, robotics, and automotive industries. By enabling continuous production with PAEK materials, INTAMSYS addresses the industry's 'last mile' challenge of achieving consistent material performance and production efficiency at scale. This development is crucial for manufacturers seeking to integrate lightweight, high-strength components into their products, such as humanoid robots and eVTOLs. The printer's ability to provide full traceability and quality verification through the INTAMQualityTM system enhances confidence in production consistency, making it a valuable asset for global manufacturers aiming for scalable, intelligent, and sustainable production.

What's Next?

INTAMSYS plans to continue driving the industrialization of high-performance materials FFF 3D printing worldwide, with the FUNMAT PRO 310 APOLLO serving as a cornerstone for smart factories of the future. The company aims to expand its reach across various industries, including aerospace, automotive, electronics, and healthcare, by offering end-to-end additive manufacturing solutions. As manufacturers adopt the 310 APOLLO, it is expected to reshape manufacturing logic, emphasizing automated, traceable, and scalable production units. This could lead to increased adoption of 3D printing technologies in mainstream manufacturing processes, potentially transforming production methodologies across multiple sectors.

Beyond the Headlines

The introduction of the FUNMAT PRO 310 APOLLO highlights the growing importance of traceability and quality assurance in manufacturing. As industries increasingly rely on high-performance materials, the ability to track and verify production parameters becomes essential for maintaining standards and certifications. This shift towards comprehensive data tracking and intelligent manufacturing systems reflects broader trends in industrial automation and digital transformation. The emphasis on sustainable production also aligns with global efforts to reduce environmental impact and improve resource efficiency, positioning INTAMSYS as a key player in the future of manufacturing.